Hello,

I am attempting to use the ADS1220 analog to digital converter with a temperature sensor cable (model 107) that I have purchased from Campbell Scientific. The sensor uses a 100K6A1iA thermistor. This thermistor has a fairly high resistance for my application's temperature range. Below is the min and max temperature for my application and the associated thermistor resistance values.

10 Celcius -> 207801 ohms

28 Celcius -> 87027 ohms

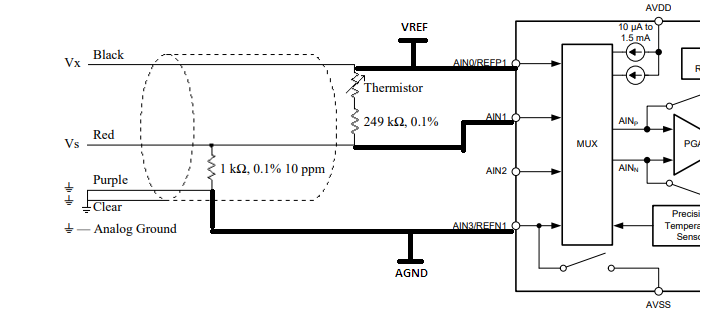

Below is a wiring diagram of the cable which has three leads. The 249K ohm resistor shown in series with the thermistor is for linearization. The manufacturer intends for a voltage reference to be connected at 'Vx' and then the 'Vs' voltage is measured. Then the 'Rs' value of the thermistor can be calculated if the 'Vx' and 'V's are both known. Then using the Steinhart & Hart equation the thermistor temperature can be calculated.

After reviewing the datasheet for the ADS1220 ADC its not completely clear to me the proper way to interface my 107 temperature probe to this part. Within the datasheet there are application schematics showing 2,3 and 4 wire RTD connections however I am not sure if these are applicable to the configuration of my 107 temperature probe.

Perhaps I could use one channel on the ADS1220 to measure the 'Vs' voltage and a second channel to measure the 'Vx' voltage. Alternatively I could potentially use an external voltage reference to drive 'Vx' and connect this point to the input voltage reference for the ADS1220. Then I should only need to measure the voltage at 'Vs' using the ADS1220 part. I don't believe the ADS1220 part makes the internally generated 2.048V reference available to a pin on the IC? If this reference voltage were available externally to the ADS1220 then I could use it as the 'Vx' voltage in my application.

I appreciate any information and guidance on how I may be able to use the ADS1220 part to measure the thermistor value in the 107 sensor cable.

Sincerely,

Sean McPeak