Other Parts Discussed in Thread: ADS1220

Dear All,

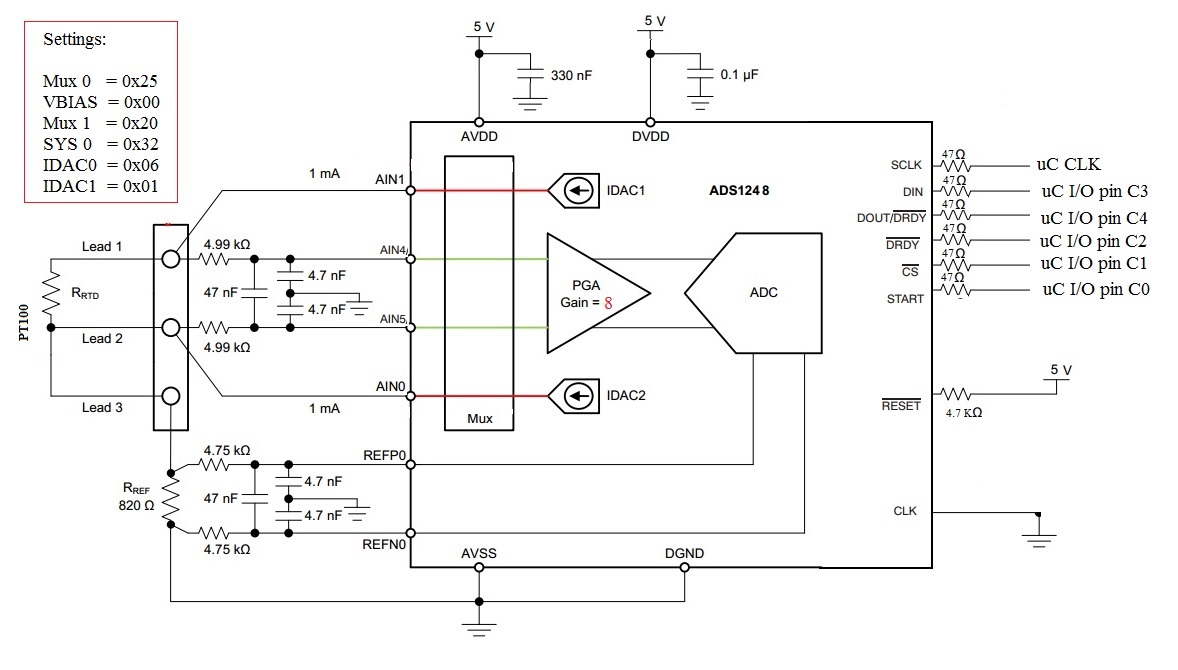

ADS1248 (with PT100) is being interfaced with Atmega Device. Software SPI has been used.

The configuration registers are written and read back to confirm the working SPI and correct settings.

Settings: Mux0=0x25 VBIAS=0x00 MUX1=0x20, SYS0=0x22, IDAC0=0x04, IDAC1=0x01,

i.e. Gain = 4, Data Rate = 20 SPS, Current IDAC= 100uA

The received value of registers are individually read from the ADC IC and 2's complement value has been taken care of for individual received bytes.

The final count is received by: (Reg1x65536)+(Reg2x256)+(Reg3)

Q1 The value of the final count is shifting a lot even for fixed temperature value( Kindly see the attached picture)

The leftmost value is manually saved temperature value, avgCount is average of 10 values(min & max removed from average),

CalcValue is current last read value and its register are saved as Reg1, Reg2, Reg3.

Q2: How to convert this value to temperature?

I have read few solutions for lookup table to avoid the complex calculation at microcontroller end.

But do i have to calibrate the lookup table value by myself? or is there any equation is involved?