Other Parts Discussed in Thread: ADS122U04, ADS1220, , ADS1235, ADS1261, ADS122C04

Hi All,

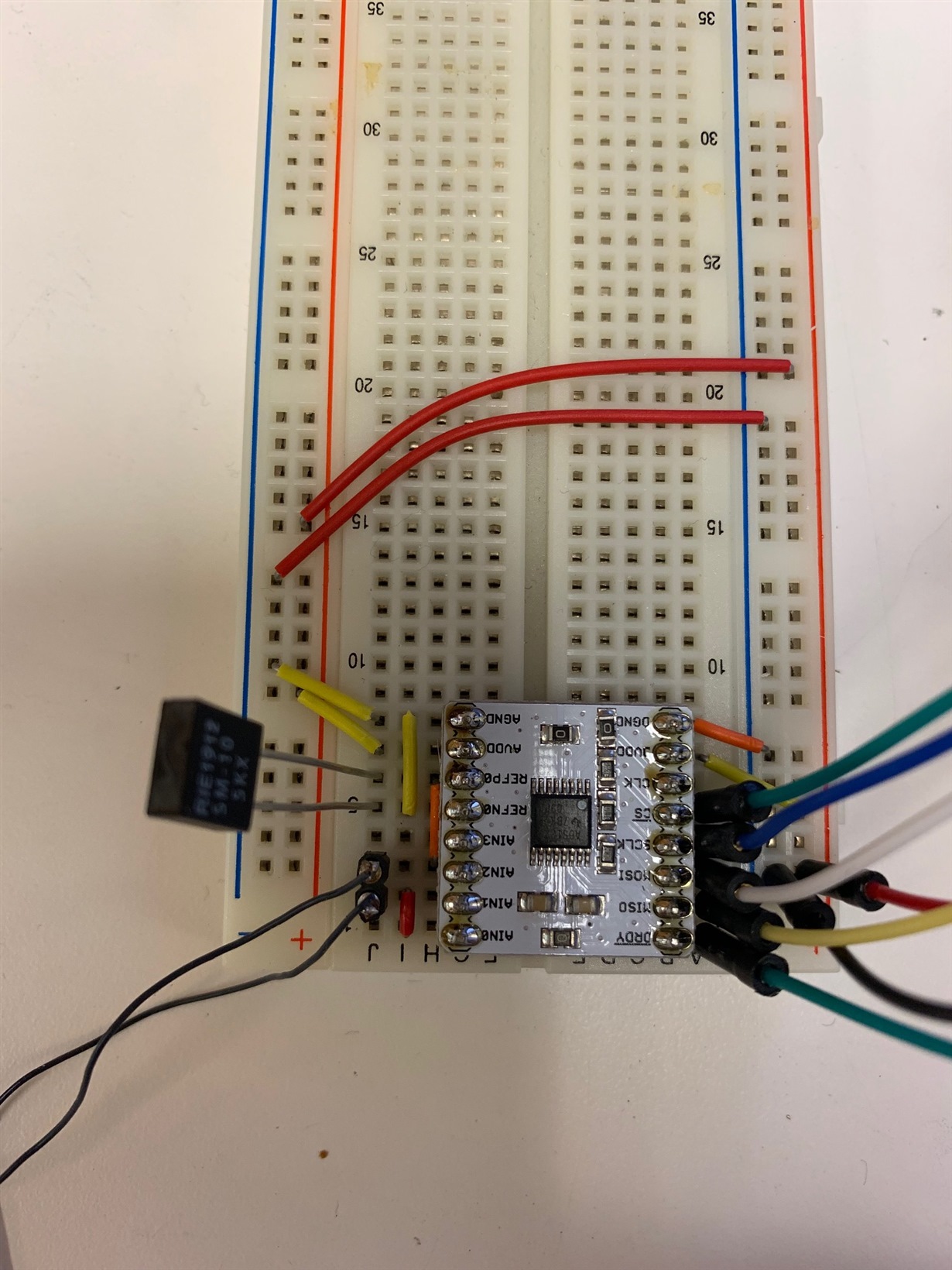

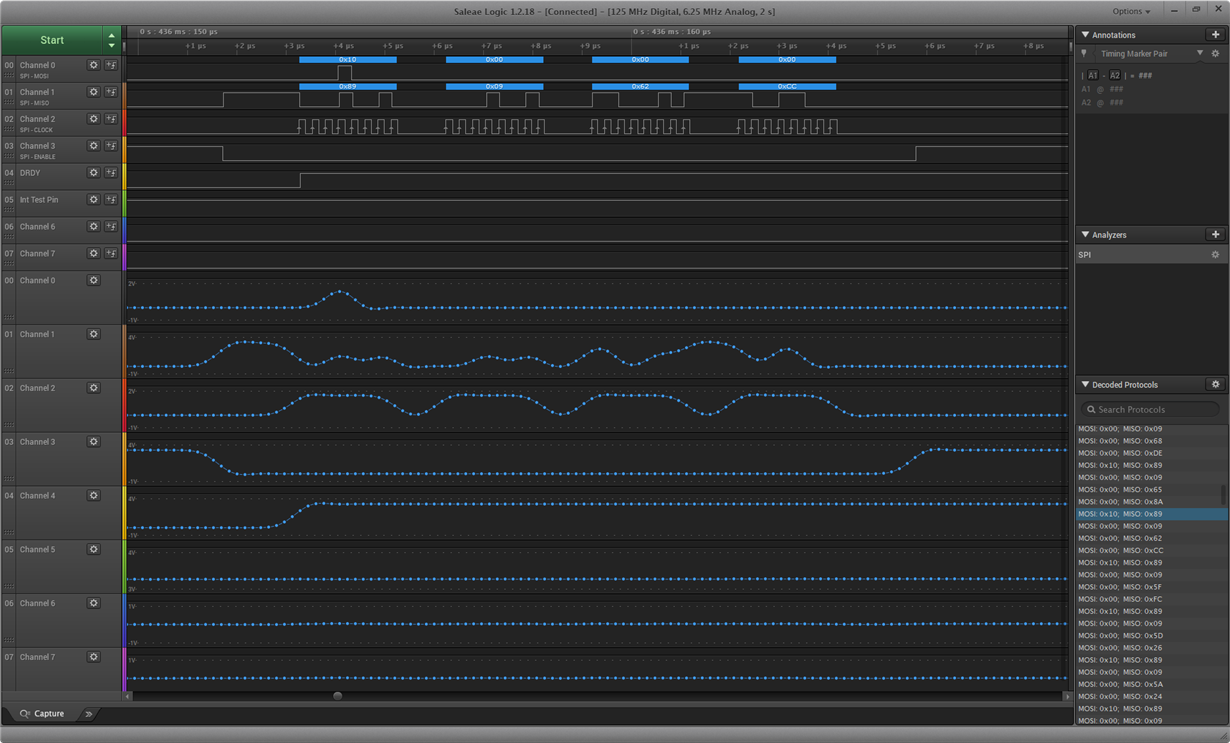

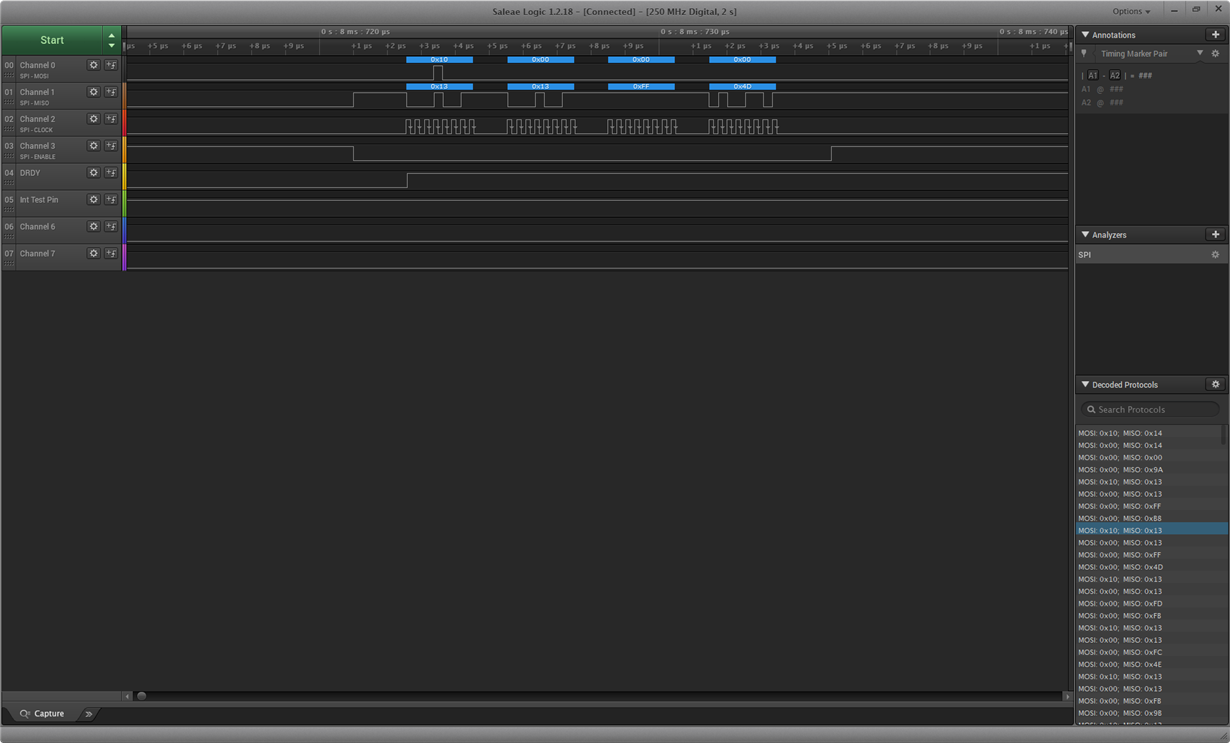

I am looking into the use of the ADS1232 or something similar for a Resistive Bridge Measurement. The sensor i am using has a resistance range of 3 ohms (normal unstretched configuration) to 22 ohms (fully stretched). I will be using a microcontroller to interface with the analog-to-digital converter. I also have a supply voltage of 3.3V or 5V. So a unipolar supply is preferred. Some initial experiments show better results with constant current excitation, and i can see that some of the TI chips support this as a built-in feature. I am able to communicate via most methods (SPI, UART etc) so i don't have a preference. I have also looked at the ADS1220, ADS122U04 and others.

I am new to resistive bridge measurements so would greatly appreciate some advice on the pros and cons of this ADC over others in your range. Higher resolution is preferred as the ultimate goal of this sensor is to characterize it for position measurements.

Thanks for your time.

Kind Regards,

Zoran