Other Parts Discussed in Thread: OPA320, INA331

I have an instance where an ADS7828 device appears stuck in a state where it is giving an erroneous digital output for the analog input.

Here are the details:

-

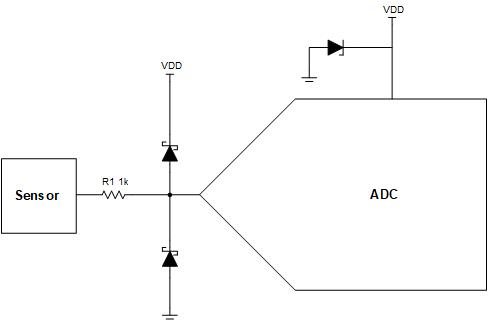

CH3 of device is connected to output of a pressure transducer.

-

Measured DC voltage for CH3: 0.24V.

-

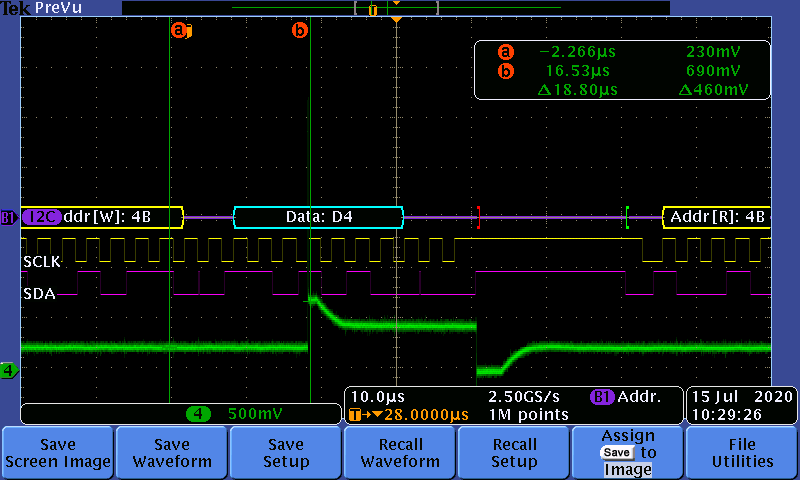

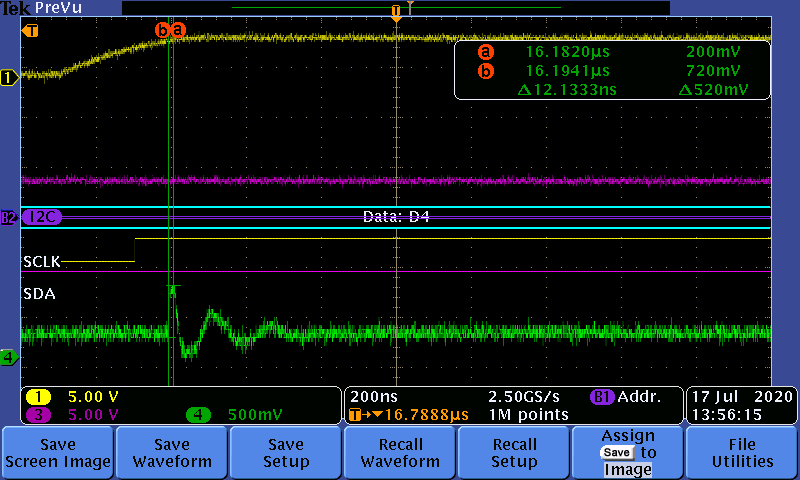

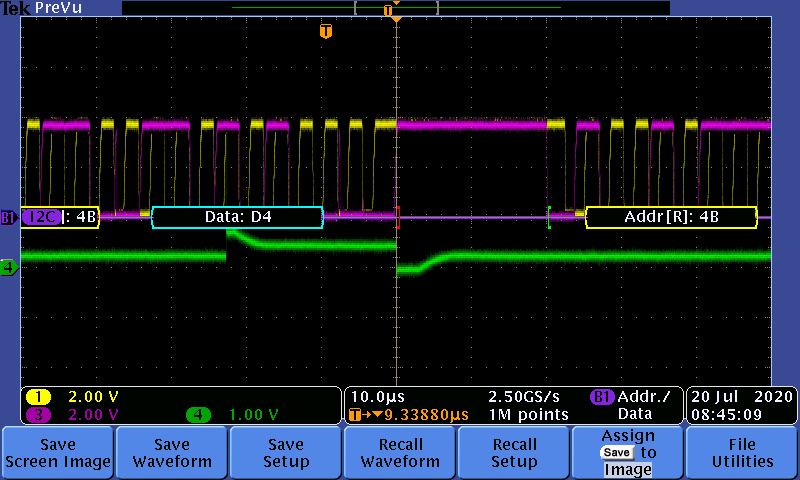

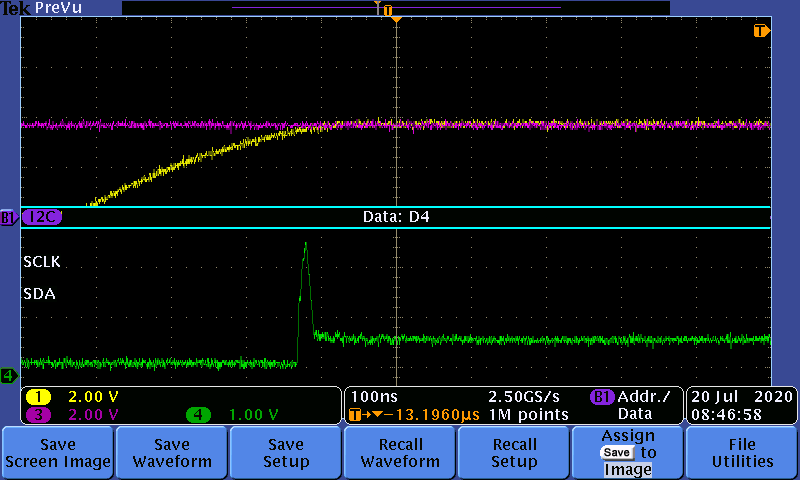

CH3 is selected by this I2C write command: 0xD4

-

Single-ended inputs

-

C2:C0 = 101

-

PD1PD0 = 01 – Internal reference off and A/D converter ON

-

-

Resulting read value = 0x05AD (1453)

One reason this is suspicious is that this board connects the output of another identical pressure transducer to a 4 channel ADC:

-

Measured DC input voltage: 0.25V

-

Resulting digital output = 0xCD (205)

Given the state of the system when the conversion is done, this result from the 4-channel ADC is what we expect, and we are trying to understand the discrepancy between the ADS7828 result and the 4-channel ADC result.

I can provide data from the other channels of the ADS7828 if needed.