Other Parts Discussed in Thread: ADS1230, LM1117

Dear sir ,

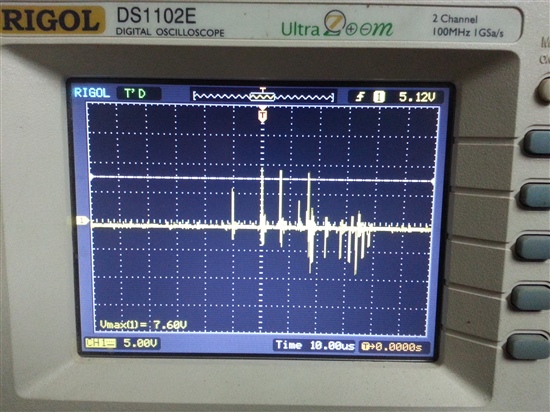

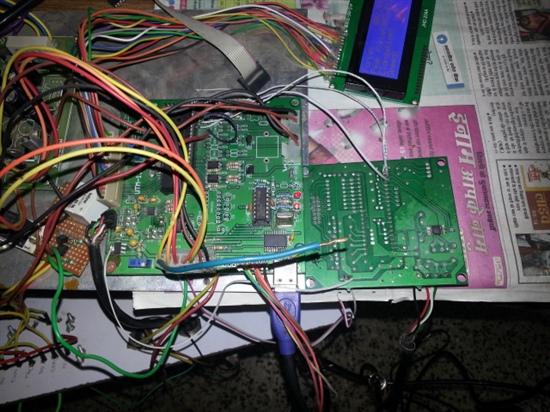

I am having an application where i am using ads1230 adc to measure the load and i am using delta AC drive to drive a 3 phase 1hp motor (havells) .The problem is the moment i run the motor there is a considerable shift in the reading of the adc.....I can see the noise on the 5V supply using the oscilloscope......I will try to explain the problem in steps:

1. The motor and drive is connected to the same extension board where my load monitoring device is connected....

2. wen i switch on the delta drive to run the motor ,the adc counts shifts by a considerable amount which is not desirable......

3.What kind of steps are taken in such situations where the ac motor creates noise in the ac mains line which is happening in this case.......Any noise on the adc -ve ref which in my case is the ground will definitely vary the reading....what could be done to remove this noise from ac motor to enter my unit....

4.my observations are :

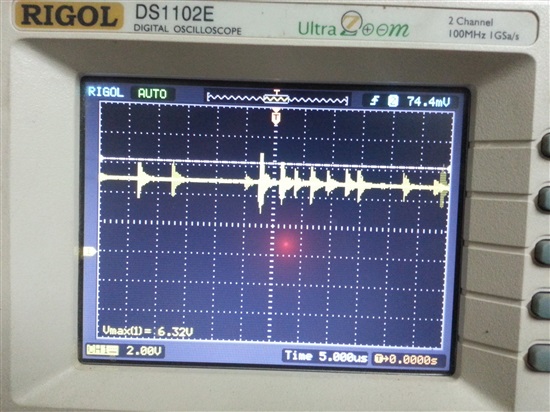

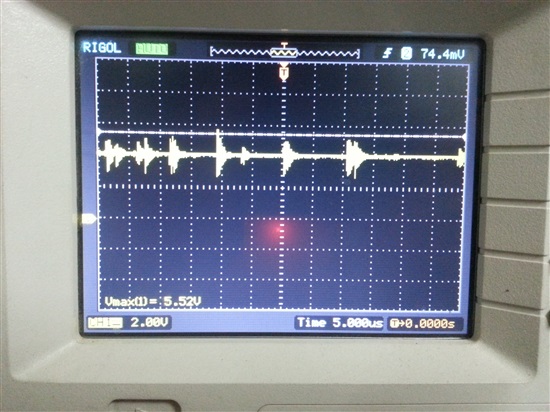

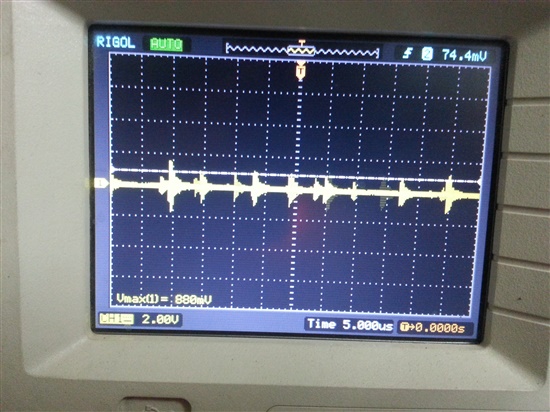

a. oscilloscope shows fluctuations between gnd and 5V which is powering my load cell, adc , adc ref......

b.if i short the 2 probes of oscilloscope with only the ground of the power supply ,,,,i see a lot of noise (of course when the motor runs)....

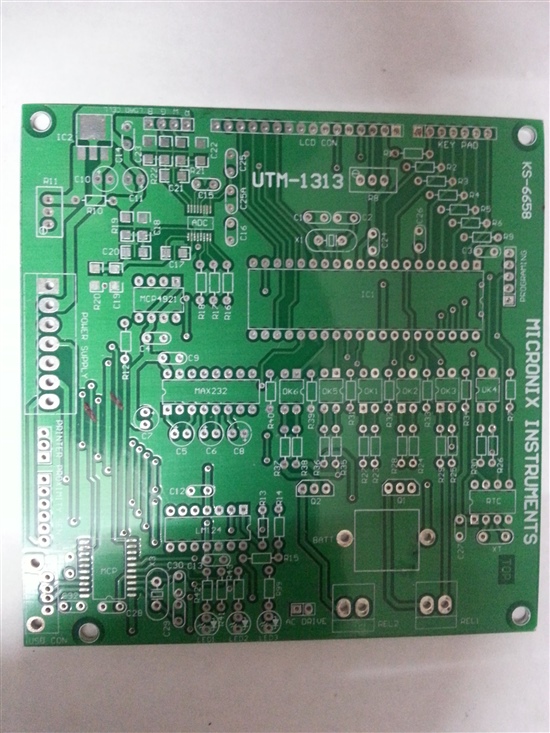

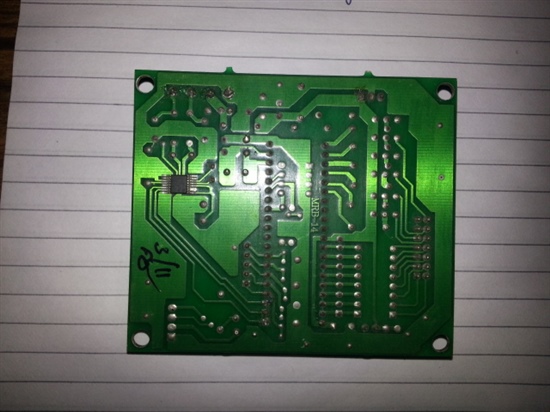

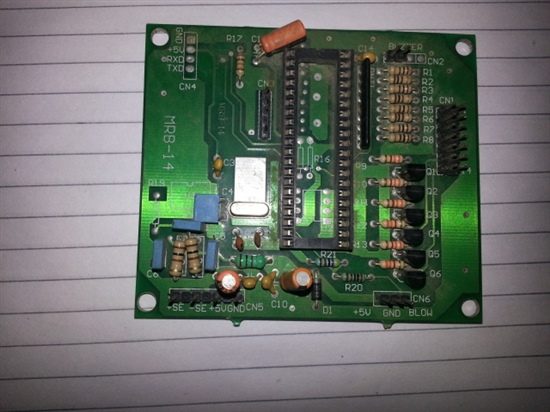

c. i am posting my schematic.......plz suggest any changes if required or any mistakes that you figure out......

5. Please suggest if any power supply filtering is required , or any change in schematic is required.....1651.UTM_changed_1.pdf