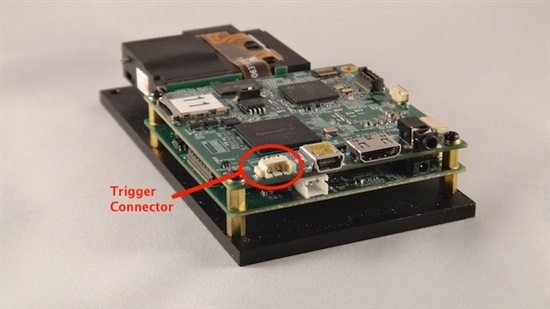

LightCrafter offers several flexible trigger configurations. The trigger connector (J7) lies at the back of the System board (top board):

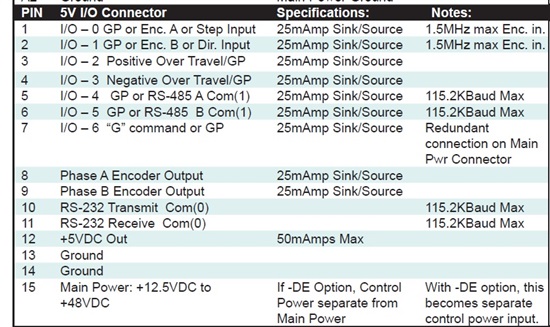

The pinout of J7 connector is:

- Pin 1 - Tigger Supply

- Pin 2 - Trigger Input

- Pin 3 - Trigger Output

- Pin 4 - Ground

Two matching four pin mating connector part numbers are:

- Molex part number: 51021-0400

- Digi-Key part number: WM1722-ND

The corresponding crimps part numbers are:

- Molex part number: 50079-8000

- Digi-Key part number: WM1142CT-ND

LightCrafter's J7's trigger input and output pins are level translated or shifted to and from the I/O supply of circuits in the System board. Out of the factory, the output trigger signal is level shifted from the 1.8V I/O supply used by the System board FPGA to 3.3V. Below is a snapshot of the schematic of these circuits. U20 level shifts the trigger input. U23 level shifts the trigger output. Note that the supply on one side of these level shifters is tied to the internal 3.3V supply, while the other side is tied to 1.8V. The level shifter are open-drain outputs with internal 10Kohm pull-ups.

In this schematic, a resistor with a value of NA_0 indicates the resistor is not populated. A resistor value of 0 indicates that a zero ohm resistor is present.

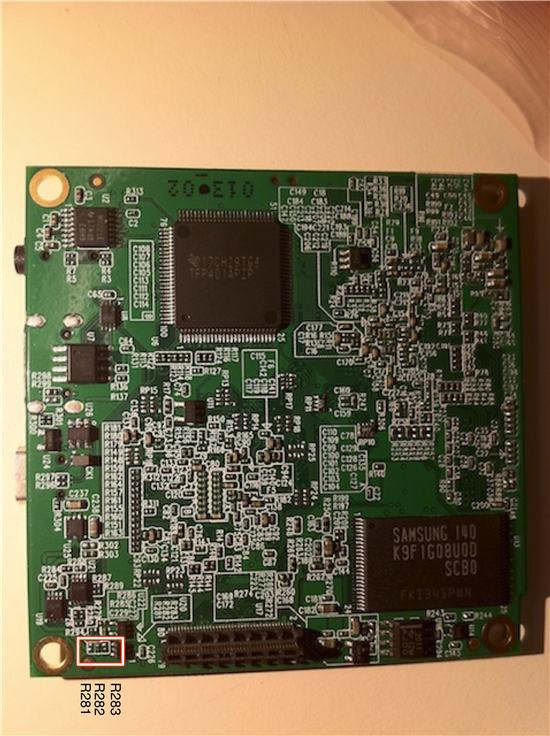

If an external 5V trigger signal is desired, then the LightCrafter board must be modified to input an external supply and use that as the level shifter input voltage, as follows:

- Install zero ohm resistor R285

- Remove zero ohm resistor R282

Then supply the external trigger voltage through Pin 1 of J7 (EXT_TRIG_VCC) and the external trigger through Pin 2 of J7 (TRIG_IN_CON).