Hi Team,

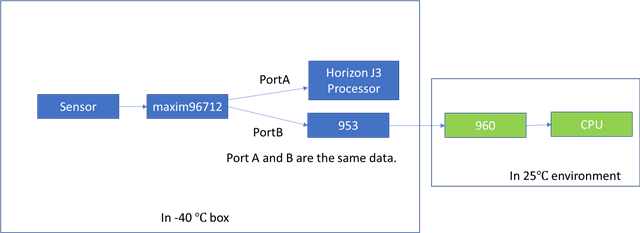

My customer now use 953+960. They could work normally in normal temp(25 ℃) but can't link successfully when power up in -40 ℃.

They now test 6* platform machine. All of their 953+960 can't link successfully when power up in -40 ℃

Here are the process they do:

1. Put the platform into -40 temp environment, wait 30 mins.

2. Power up this platform.

3. 953+960 status:

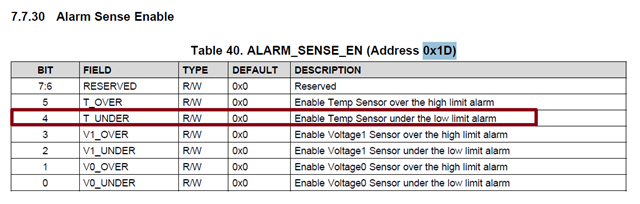

1) 960 Lock state is low. The I2C address of the 953 cannot be accessed, and the CRC status of the 960 is reported incorrectly

2) 960 Lock state is high. The I2C address of the 953 cannot be accessed, and the CRC status of the 960 reports an error

3) 960 Lock state is high. Can go to the I2C address of 953, 960 and 953 CRC status both report error

4) 960 Lock state is low. Can go to the I2C address of 953, TI960 and TI953 CRC status both report error

The above four phenomena are constantly changing. Phenomenon 1) has a higher probability and is in this state for a long time. Phenomenon 2 / 4 probability is low.

Could you kindly help for this?