Part TPD4E1B06 is used to protect a PTH hand soldered connector and is in close proximity to it. After the hand soldering with a no clean solder the PTH pads are brushed as recommended by the solder supplier,

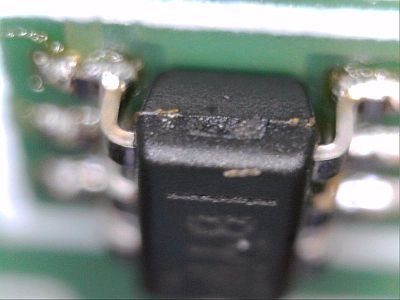

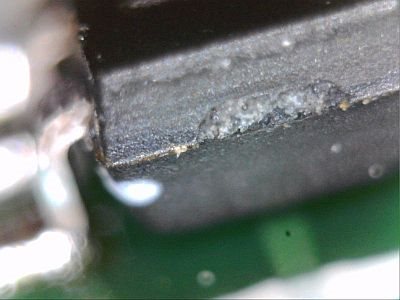

After running the unit we are seeing some chemical effect at the device at the join between the two half's of the plastic package at each end, and the part goes leaky. Once this problem has occurred the fault stays with the part but is intermittent and pressing on the package can trigger it.

It appears to be to do with the flux which seems to get brushed over the part.

No other SMD parts near by show the same issue. I have pictures of the effect which seem to follow the package join line. Is there something about this package that makes it more susceptible, the package join on some parts looks like it has small holes allowing the flux entry?

We have to retrieve a large number of products from the field and remove these devices. We will shortly be starting new manufacture and wondered whether we should be using different parts.