Hello TI Community,

Has anyone experienced with using an RS-485 transceiver to communicate with a CAN bit stream from a u-controller?

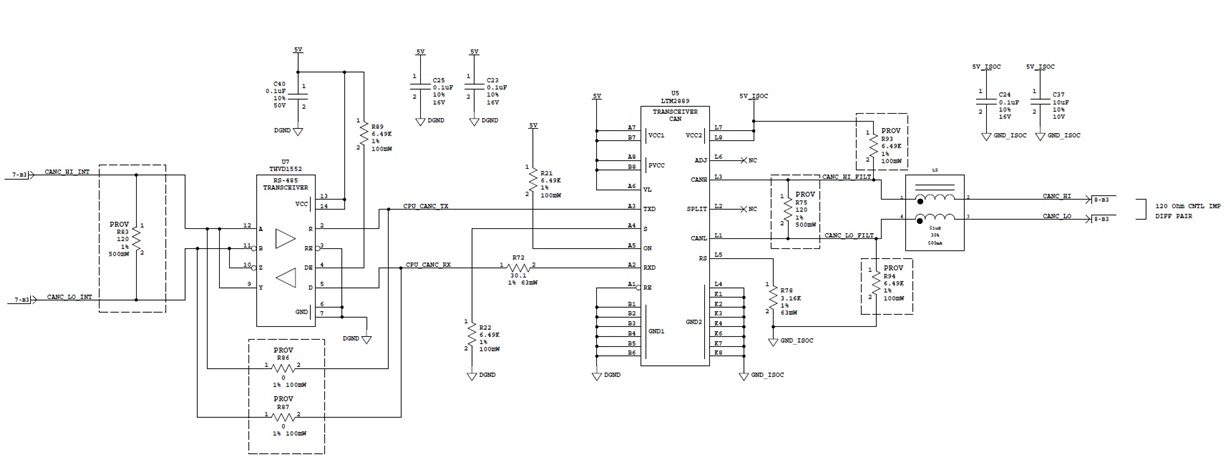

I'm communicating from one board to another in a potentially noisy environment so going from the u-controller CAN Tx/Rx pins, to an RS-485 (full duplex), to an RS-485 on the other board, to the CAN transceiver, then out of the box to interface to another CAN transceiver down stream. It seems like this could work, but would like some feedback.

Thank you for your support with this.