Other Parts Discussed in Thread: ISO7741

Hi,

I would like to understand better the criteria for selecting an isolating component for reinforced insulation:

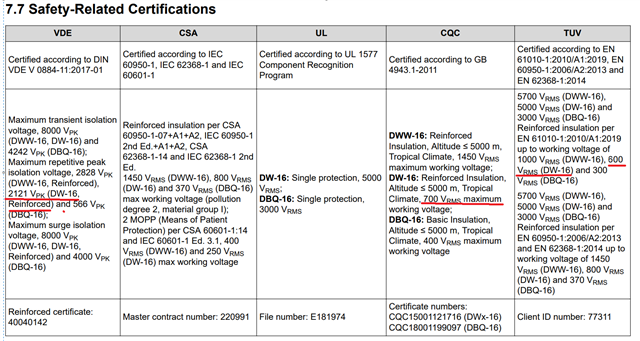

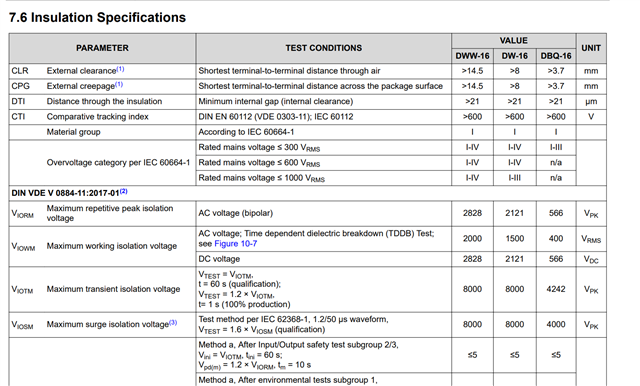

If we take the ISO7741-Q1 component, there is a big discrepancy on how much the component can withstand in terms of Maximum Working Voltage (If I understood it is VIOWM parameter):

The overall insulation specifications are specifed for the DIN VDE V 0884-11 standard, which would rate the VIOWM as 1500Vrms:

- For the automotive market, how can we determine if the component would be valid for e.g. 1000Vrms continous working voltage if there are certifications (e.g. CQC and TUV) that show ratings below that?

- What are the differences in requirements regarding the different normatives?

- Does these norms/requirements apply to Transformers as well?

Thanks