Other Parts Discussed in Thread: ISO1541, , ISO7741, SN65HVDA100, ISO7841, TLIN1029-Q1, ISO7721, ISO1042, ISO7742, LP2951-Q1, ISOW7841, SN6501

After reading the post Operational Principle of a Bidirectional Isolator (for LIN and I2C Interfaces) by Thomas Kugelstadt, I was rather surprised to discover, that neither the two referenced isolators (ISO1540 and ISO1541), nor any other isolators in the TI portfolio allows bus (or supply-) voltages above 5V (nominal).

This means that none of the isolators are actually suitable for use on the LIN bus - a bidirectional open collector bus, with pull-up resistors typically connected to a +12V supply. Although very similar in electrical characteristics to the I2C/TWI bus, the supply voltages makes all the difference in support parts availability.

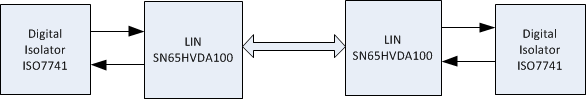

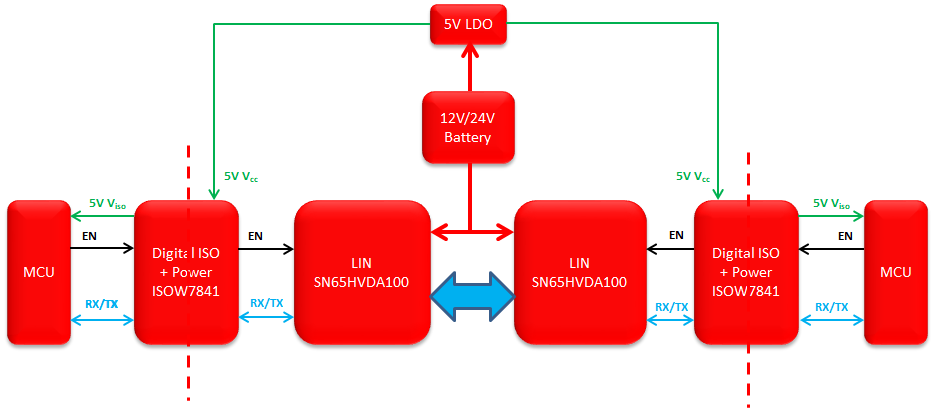

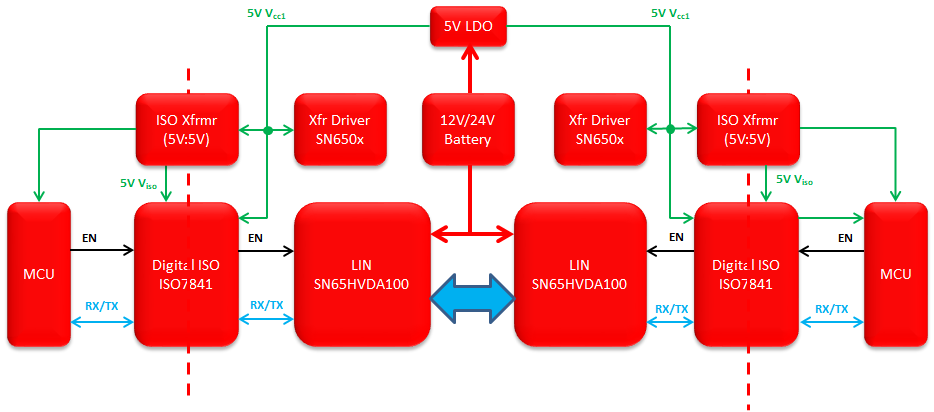

Although the ISO1540 and other isolators could possibly play a part in a LIN bus isolation circuit, by isolating the digital MCU side of the LIN bus transceivers (isolating RX, TX, EN), this solution would still require jumping through hoops to stay within the isolator Absolute Maximum voltage ratings of 6V, and the isolation would still not be optimal. Also, none of the LIN transceivers have native isolation support.

Is it a due to the LIN bus' automotive roots that no isolation circuits are available? While most automobiles does have a common ground (chassis), isolation of the LIN bus would still be beneficial, or even crucial, to overcome ground loops and connecting vehicle elements (e.g. tractor + trailer), where high potential differences may exist.

Is there any "best practice" for isolating segments of - or nodes on - the LIN bus, or would it require piecing the components together from discrete isolator parts?

Any help would be appreciated.