Other Parts Discussed in Thread: ISO7840,

Hi

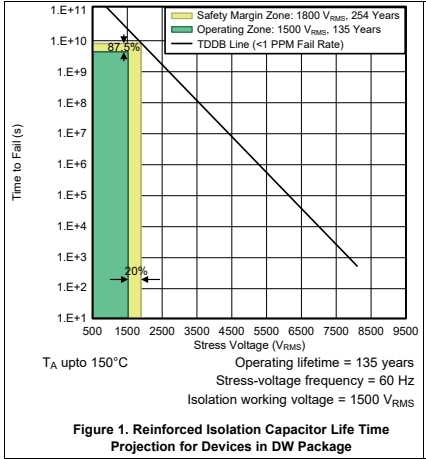

At present, 2 ISO7841 and 12 ISO7840 are used. During a certain normal output, 2 ISO7841 are damaged, and some pins are short-circuited to ground, which is suspected of withstand voltage. Our design refers to the following picture.

As shown in the figure below, it can reach a service life of 3 years under 2500V

1. According to the usage scenario in the above picture, whether the above chip is in accordance with the design under 2400V isolation voltage (usually used for pulse output and will not always work at 2400V), is there any technical risk;

2. The problems are all with ISO7841, whether it is different from ISO7840;

3. This chip claims that the withstand voltage can reach a voltage of 8000Vpk, which is quite different from the actual voltage used. How should we look at this part, or directly evaluate the isolation voltage and life according to the above figure;