Other Parts Discussed in Thread: SN6501

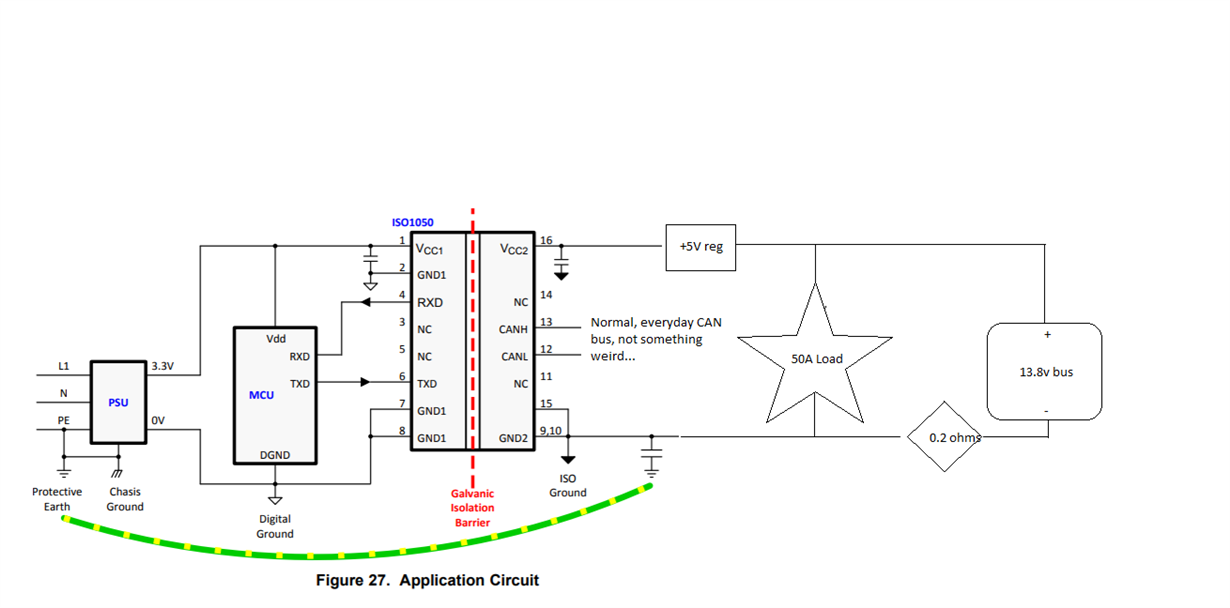

My application is an update to an existing design. This device is a 200W class electric motor actuator for use on a 12VDC vehicle using CAN. The legacy connector between the device and the vehicle has four pins, CAN_H, CAN_L, +12VDCin, and GND. I don't have the freedom to modify this connector.

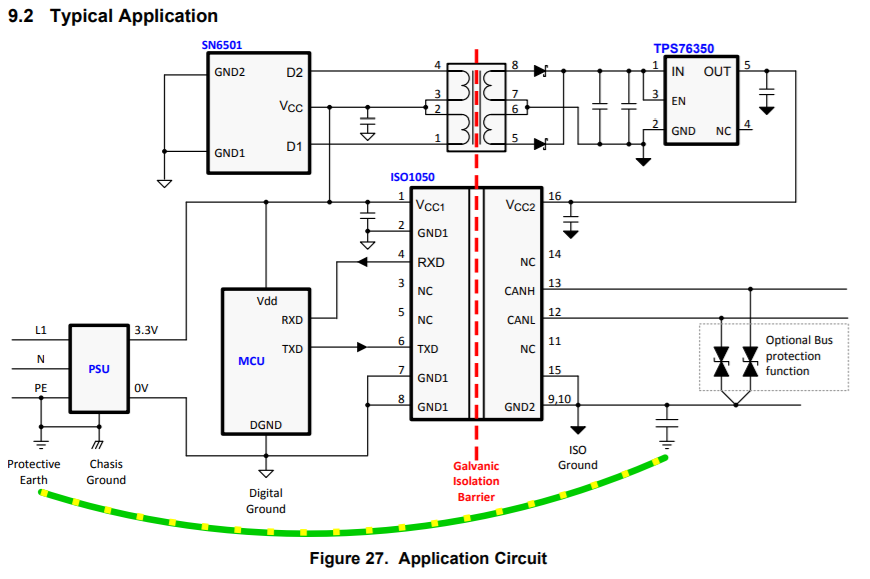

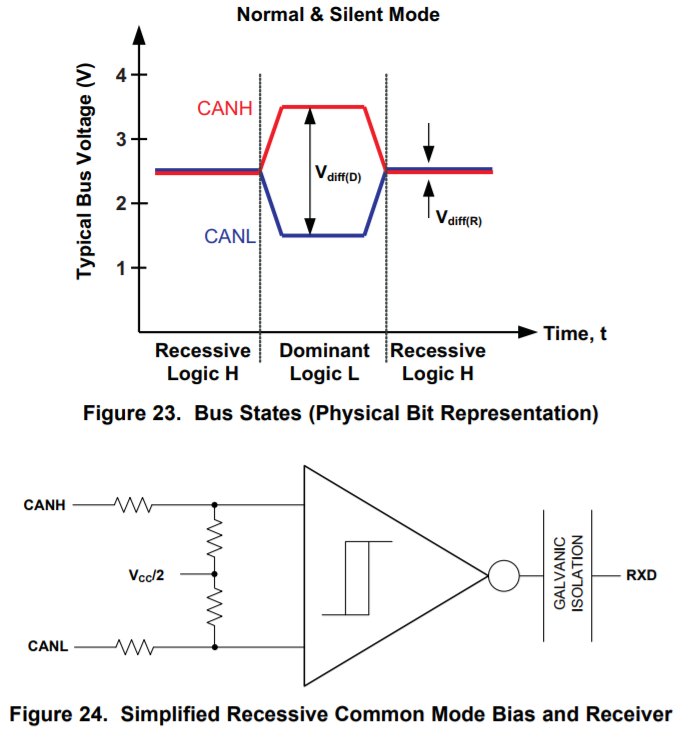

I am concerned about this configuration. Under full power, ~20A is pulled off the vehicle. If the GND path has much more than 0.100 ohms resistance, the CAN lines will be appear to have violated the common mode specification from the perspective of the CAN transceiver in our product. We could add isolation around the CAN transceiver in the new design, however it still needs some reference for the CAN bus (?). The floating supply and the transceiver need to have a 0v reference to properly locate its own output relative to the vehicle bus.

I've seen the reference designs from TI and others, however they don't answer this question conclusively. A split termination with Vsense tied to the center tap might be a solution if this device was one of the bus terminators. Unfortunately, I can't assume that this device will always be allowed as a bus terminator. Could large value resistors be used instead of 60 ohms to avoid loading the bus, yet still supply a pseudo-reference?

Certainly, this isn't the first time this has come up. Is there an industry accepted practice to solve this challenge?