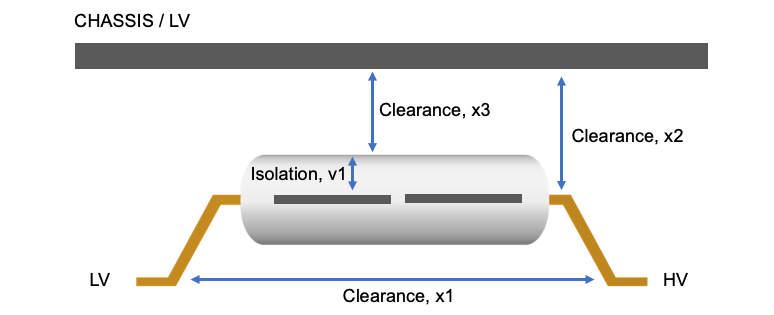

My customer has very limited height for the components on their PCB and isolation guidelines need to be followed between the top of package and their casing. The allowed height of components without isolation (towards the package top) is 2.5mm and for components with (at least) basic isolation is 3.0mm. The ISOW7821F has a height of 2.65mm and could only be used if it offers basic (reinforced would be even better) isolation towards the top of the package.

Thanks

Josef