FAQ: Logic and Voltage Translation > Quality and Manufacturing >> Current FAQ

In short, this is not an extra pin and it is nothing to be concerned about. It is part of the support used in the manufacturing process.

-

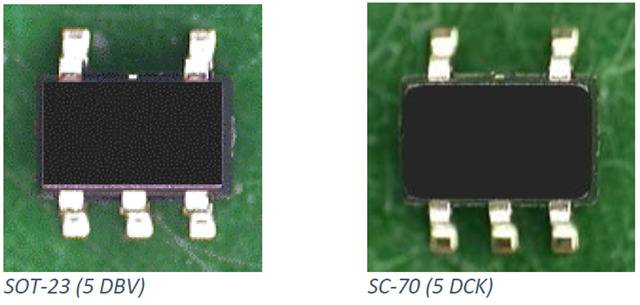

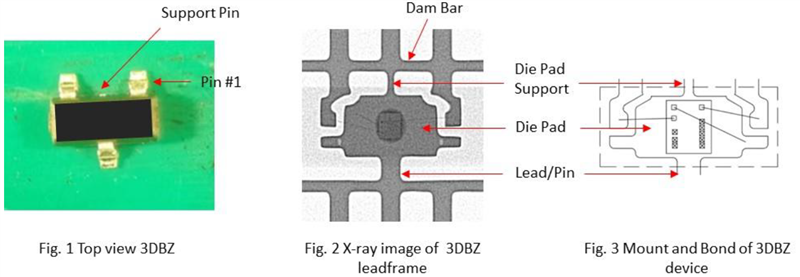

SOT (Single Outline Transistor) packages have been in the industry for over three decades. Some of the packages like SOT-23 and SC-70 have become very high volume and requiring multiple manufacturing sources to mitigate supply disruptions. With so many suppliers in the market, there are some subtle differences between manufactures. One feature that often draws interest is what appears to be a clipped lead. The feature is referred to as a “Support Pin” and shown in Figure 1 below. Figure 2 shows how this “Support pin” is used as part of the overall leadframe design for a 3 pin, SOT-23 package to hold the pad where the die will be mounted. In addition to supporting the die pad, the pin also helps support the ‘Dam Bar” (also shown in Figure 2) to prevent excessive mold flashing. The “Support pin” is removed during the trim and form process after the encapsulation process. In some cases, suppliers have simplified manufacturing lines and use a single LF to support 5 and 6 pin SOT-23/SC-70 packages. The 5-pin option has a lead trimmed between pins 4 and 6. When a “Support pin” is not present, it means the manufacturer is using another technique to how the die pad and minimize mold flash.

Below are some examples of TI packages with a “Support pin.” TI’s package outline drawings do not capture the Support pin, though both options are sold under the same part number. TI does consider these two variants to be interchangeable as there is no change to form, fit and functionality. With the “Support pin” trimmed close to the mold compound, it cannot be soldered to the PCB and there is no increase in a shorting risk compared to a fully populated package.