Hello.

I made SSI-sensor-2ch-IF BOARD with TM4C1290NCPDT.

Currently debugging.

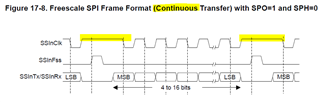

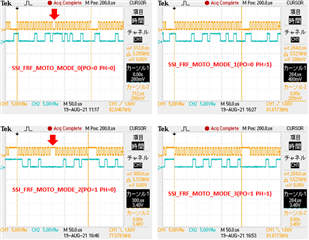

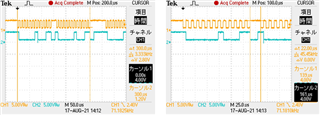

In order to read the data from 25bit-SSI-sensor, CLK13bit was output twice by the SSI module.

However, as Charles worried, there is a delay of 16us or more between 13bit CLKs and it is not possible to read correct data continuously.

Is there a way to read the data by continuously issuing 26-bit CLK?

CLK may be 32 bits.

Waveform CH1: CLK, CH2: sensor DATA

The current coding is as follows.

--------

sysclk = MAP_SysCtlClockFreqSet((SYSCTL_XTAL_20MHZ

|(SYSCTL_OSC_MAIN)|(SYSCTL_USE_PLL)) ,20000000);

MAP_SSIAdvModeSet(SSI1_BASE, SSI_ADV_MODE_LEGACY);

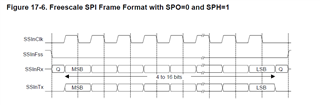

MAP_SSIConfigSetExpClk(SSI1_BASE, sysclk, SSI_FRF_MOTO_MODE_0,

SSI_MODE_MASTER, 90000, 13);

while(!SysCtlPeripheralReady(SYSCTL_PERIPH_SSI1));

MAP_SSIEnable(SSI1_BASE);

while(MAP_SSIDataGetNonBlocking(SSI1_BASE, &d[0])) ;

for(i=0;i<2;i++)

{

MAP_SSIDataPut(SSI1_BASE, 0); //out 13CLKS

MAP_SSIDataGet(SSI1_BASE, &d[i]);

}

--------

INO