Hi,

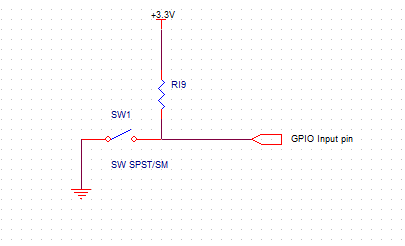

Im using TM4c1233h6PGE for Industrial Automation. i want to have 16 Push button switches connected to port L & G. I have connected external pull up resistor to these input pins. I used the flowing code for configuring it as input pins

GPIODirModeSet(GPIO_PORTG_BASE,ALL_GPIO_PINS,GPIO_DIR_MODE_IN);

GPIOPadConfigSet(GPIO_PORTG_BASE,ALL_GPIO_PINS,GPIO_STRENGTH_2MA, GPIO_PIN_TYPE_STD);

GPIOIntTypeSet(GPIO_PORTG_BASE, ALL_GPIO_PINS, GPIO_RISING_EDGE);

GPIOPinIntEnable(GPIO_PORTG_BASE,ALL_GPIO_PINS);

//Input Interrupt - PORT L

GPIODirModeSet(GPIO_PORTL_BASE,ALL_GPIO_PINS,GPIO_DIR_MODE_IN);

GPIOPadConfigSet(GPIO_PORTL_BASE,ALL_GPIO_PINS,GPIO_STRENGTH_2MA, GPIO_PIN_TYPE_STD_WPU);

GPIOIntTypeSet(GPIO_PORTL_BASE, ALL_GPIO_PINS, GPIO_RISING_EDGE);

GPIOPinIntEnable(GPIO_PORTL_BASE,ALL_GPIO_PINS);

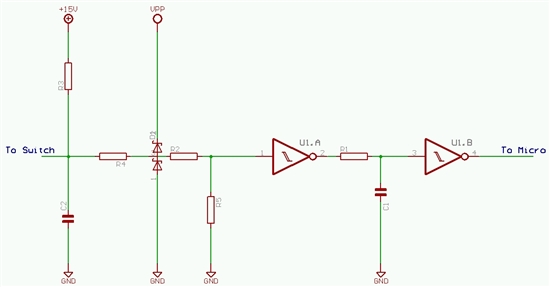

But with this setup my input pin are not working after prolonged usuage. Its damaging my IC input pin. so i have two questions

1. In software segment, how to configure a input pin with external pull up resistor.

2. Im using 2MA WPU per pin as per code, which will account to 18MA circuitary per side for high industry application, if the internal pull up resistor is used, which will make input pins not to work. so how to solve the problem. what is concept of sinking current with input