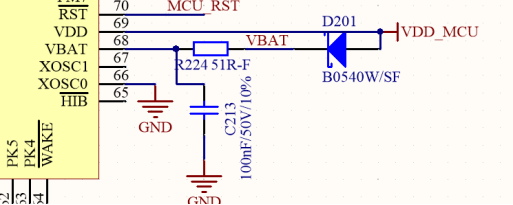

We use TM4C129EKCPDTI3R, The POWER indicator light of our equipment is always on when powered by the POWER supply of 3V3, and the POWER supply of the chip is also powered by the POWER supply of 3V3. We use the chip VBAT pin and the chip register to save the POWER off data. When the POWER supply of the equipment is disconnected, the POWER light of the equipment will keep a slightly bright state.By testing the voltage and current, the chip VBAT pin current is significantly increased (the current is from the battery). The 3V3 loop has a voltage of 1V6, but the 3V3 loop has no power supply.The VBAT pin is connected to the battery positive pole, and the battery voltage is 3V3.TI support to solution the problem, analyze the reason for the pin to electricity rate is not greater than 0.7 V/us, by the RC circuit, reduce electricity rate, confirm the resistance value of 51 r, capacitance value is 100 nf follow-up until solve the problem, but in a batch production and found that the power lamp light phenomenon, by adjusting the resistance, we further reduce electricity speed of the pin, the issue is resolved for the time being.May I ask: can we solve the problem by increasing the resistance value and reducing the power loading speed? What is the reason for the recurrence of this phenomenon?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.