Hello Expert,

Currently, with the combination of "LAUNCH XL-F28027F" + "BOOST XL-DRV8301" . Our customer is driving a motor, but in the high rpm range (20000 to 30000 [RPM]) with the load applied, The sinusoidal waveform of the current is distorted and has a whiskered shape.

The brushless permanent magnet motor is rotated by the sensorless vector control of InstaSPIN-FOC.

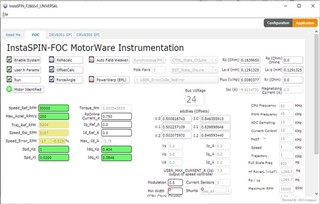

(Motor equipment constants used: Number of counterpoles 3, phase resistance 0.163 [Ω], Φa = 1.61 × 10-3 [Wb], Ld, Lq = 0.129 [mH])

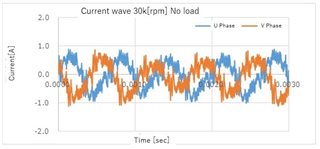

The figure below shows the phase current waveform of the motor when rotating at 30k [rpm]. In the low rpm range, the waveform shape is close to a sine wave, but in the high rpm range such as 30k [rpm], Although it is rotating, the waveform is disturbed as shown in the figure below. At this time, the motor is in a no-load state.

The each gain setting values are as shown in below.

Regards,

A.Fujinaka