Other Parts Discussed in Thread: CONTROLSUITE

I am trying to implement Universal Motor Control lab with own control card F280025C, own hardware board with 1 hp PMSM motor.

1. In build2, motorVars_M1.speed_Hz is not following the motorVars_M1.speedRef_Hz.

2. As mentioned in the document spruj26.pdf, I have changed the following parameters according to our motor

#define USER_MOTOR1_FREQ_LOW_Hz (10.0f) // Hz // Hz - suggested to set to 10% of rated motor frequency

#define USER_MOTOR1_FREQ_HIGH_Hz (110.0) // Hz // Hz - suggested to set to 100% of rated motor frequency

#define USER_MOTOR1_VOLT_MIN_V (10.0f) // Volt // Volt - suggested to set to 15% of rated motor voltage

#define USER_MOTOR1_VOLT_MAX_V (70.0f) // Volt // Volt - suggested to set to 100% of rated motor voltage

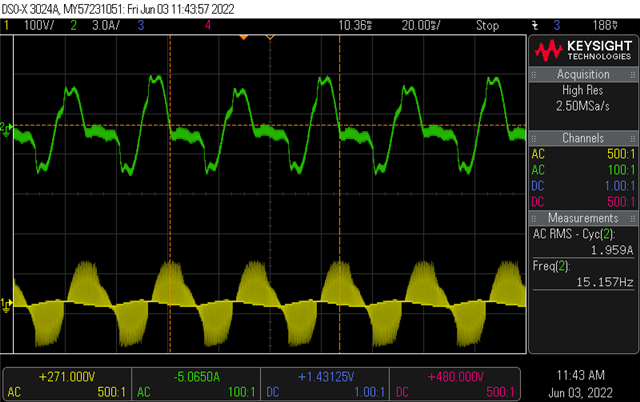

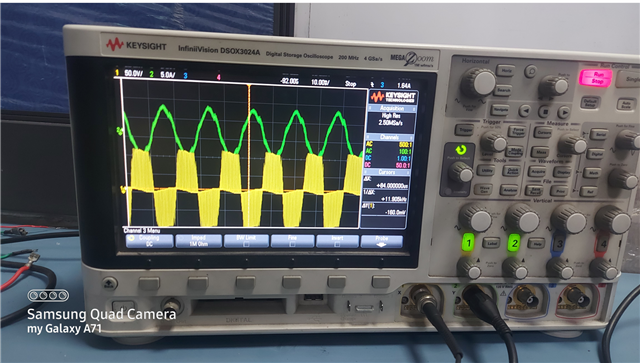

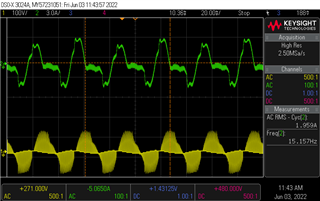

but current and voltage waveforms obtained are not as provided in the document.

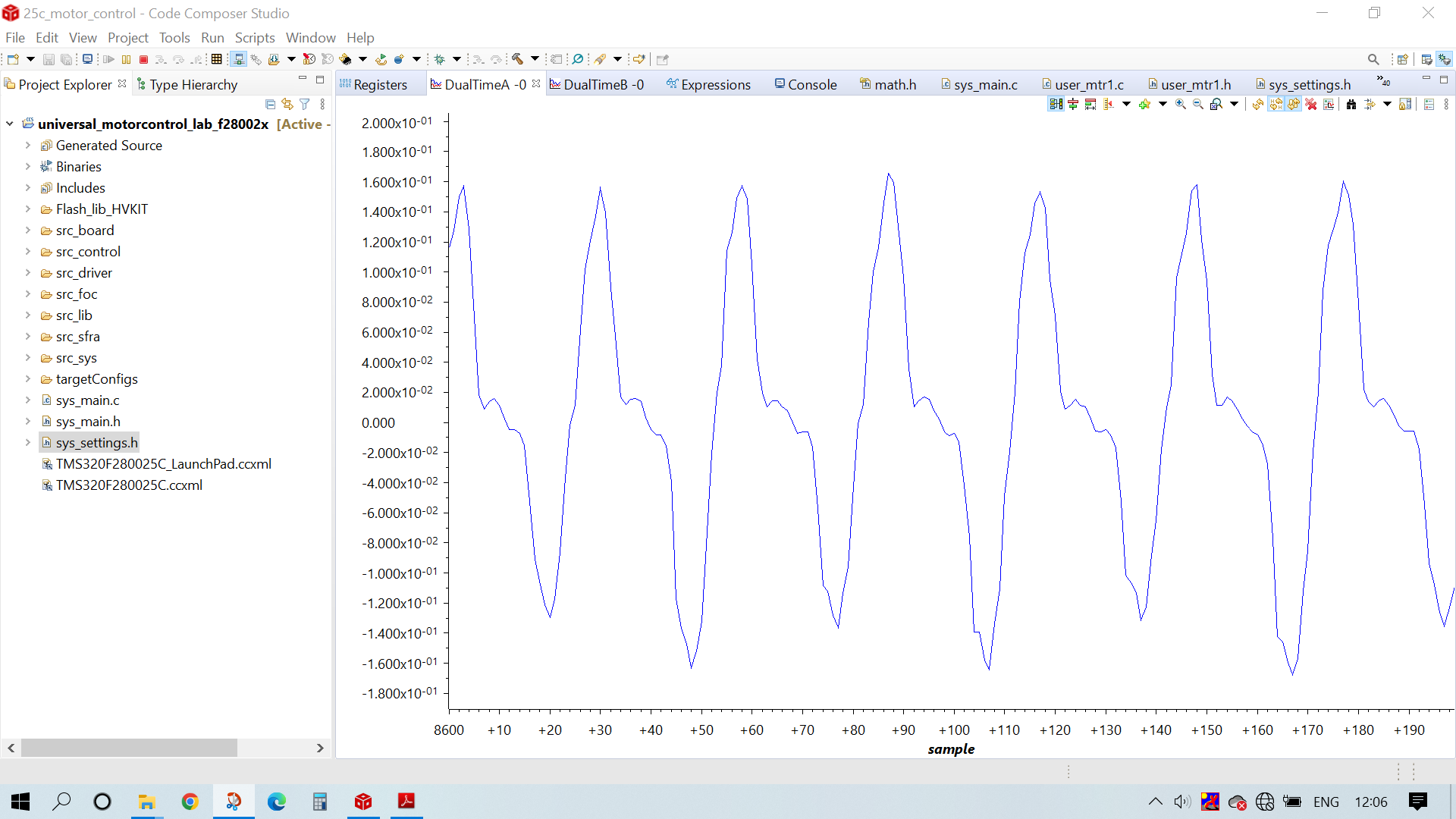

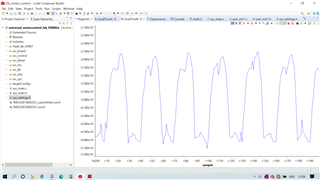

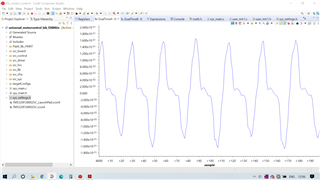

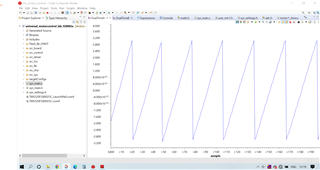

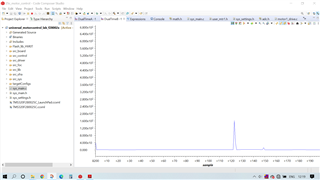

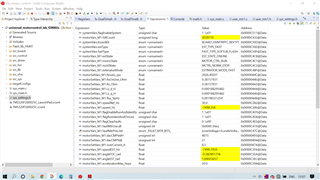

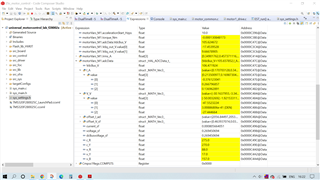

Please look into the following attachments of obtained datalog waveforms and the expression window

datalog voltage waveform datalog current waveform

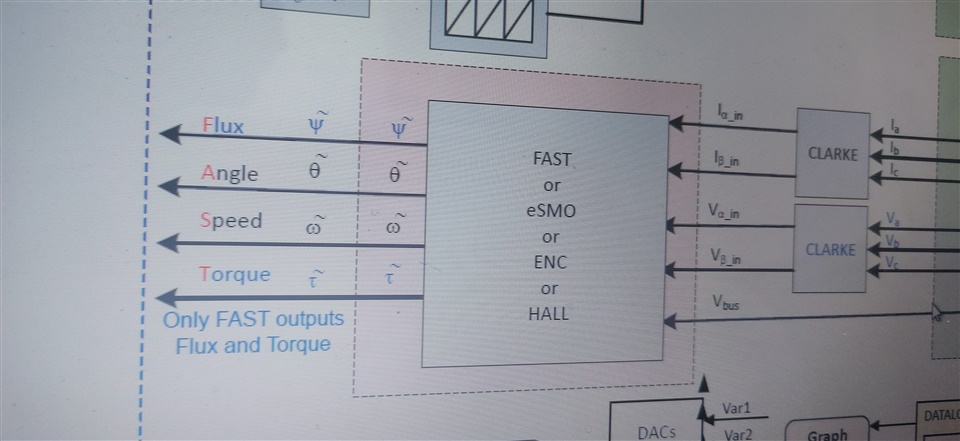

force angle generator Motor rotor angle from estimator

expression window

kindly look into this issue.