Other Parts Discussed in Thread: TMS320F28388D

Hi,

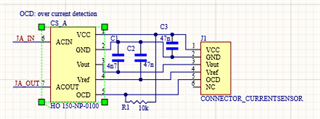

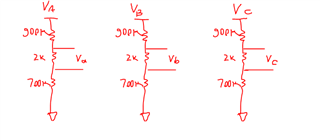

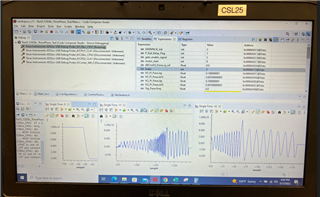

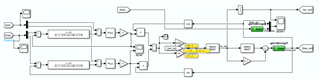

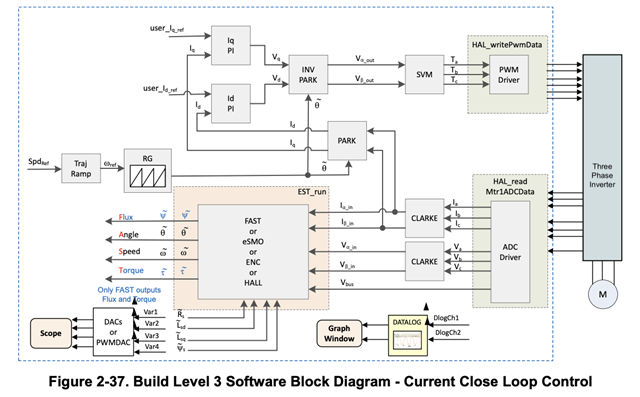

I have a costumed deigned inverter with TMS320F28388D and a low inductance (28.5uH per phase), high speed (120,000RPM) PMSM motor. I am going to implement the sensor-less FOC on this board. I have implemented I/F control based on the following block digram

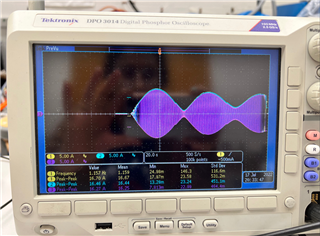

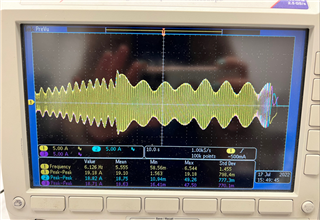

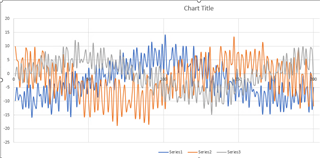

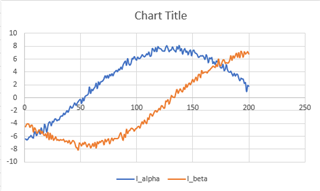

By applying 0A to Id_ref and 5A to Iq_ref, the motor gets started. However, I expect to see the iq and id merging to their dc reference value, I see that the iq and id currents change like a sinusoidal waveform. my trajectory is a frequency function of time as (f= alpha * t^2), where alpha is equal to 0.5. What changes I should make to current controllers' kp and ki to have a nice id and iq following their references; currently, the kp =0.1, ki = 3.125., PWM frequency = 50kHz, and interrupt frequency = 32250Hz.

Thanks in advance,