Other Parts Discussed in Thread: C2000WARE

Hi team,

Here's an issue from the customer may need your help:

The customer uses Launchpad-F280025C+DRV8323Rs development boards with the following torque control issues during debug:

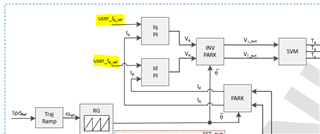

1) The speed control is used for both the source codes DMC_level_3 and DMC_level_4 in universal_motorcontrol_lab. DMC_level_3, although the current is closed loop (no speed loop is included), still need to assign a value to motorVars_M1.speedRef_Hz.

The customer believes that the torque control mode should not be affected by motorVars_M1.speedRef_Hz and that setting only the current level allows the motor to operate properly. However, currently in DMC_level_3, if motorVars_M1.speedRef_Hz = 0 is set, the motor will not function properly.

2) Try changing the setting of obj->operateMode = operation_mode_TORQUE;//operation_mode_speed; in the initMotor1CtrlParameters function but still failed to implement torque control.

They would like to know what code modifications are required based on DMC_level_3 to implement torque control? Could you help check this case? Thanks.

Best Regards,

Cherry