Other Parts Discussed in Thread: C2000WARE, , SYSCONFIG

Tool/software: Code Composer Studio

dear yanming,

Build Level 2 & 3:

We have set these parameter as per specification:

#if (USER_MOTOR1 == Voepl_ODU_compressor_motor) //added by Babaji Nemnar 18032023

#define USER_MOTOR1_TYPE MOTOR_TYPE_PM

#define USER_MOTOR1_NUM_POLE_PAIRS (3)

#define USER_MOTOR1_Rr_Ohm (0.0)

#define USER_MOTOR1_Rs_Ohm (0.838)

#define USER_MOTOR1_Ls_d_H (0.0085737)

#define USER_MOTOR1_Ls_q_H (0.01210875)

#define USER_MOTOR1_RATED_FLUX_VpHz (0.377903223) Note: this parameter is not present in the specification,Please guide how to set.

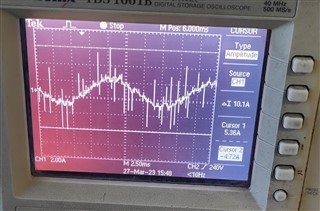

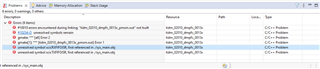

After Run the Code:

Copressor worked for 2 second & stop.Refer attachment expression window with queries.

Please guide.