Other Parts Discussed in Thread: TIDM-02010, MOTORWARE

Dear support team.

I'm working with my own motor and DRV8353RS, 3 shunt and TMS320F280025 lanch pad.

The motor is runing fine I just have a small issue during flying start.

I use universal motor control lab from SDK 4_02_01_00.

As discussed before, those parameters as been set:

obj->flagEnableFlyingStart = true;

obj->flyingStartTimeDelay = (uint16_t)(objUser->ctrlFreq_Hz * 0.5f); // 0.5s

#define USER_MOTOR1_SPEED_FS_Hz (3.0f)

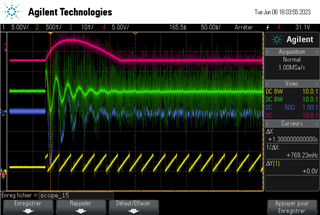

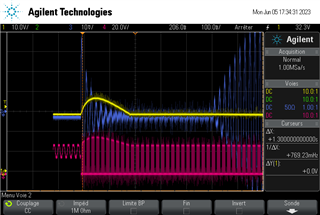

During flying start I have an overvoltage (about 10V for 28V power supply), see below:

Yellow : DC voltage

Blue : current in the motor (10mV=500mA)

Pink : MOT B voltage

As you can see, when the flag motorVars_M1.flagEnableRunAndIdentify is set to 1, the current take a few ms before regulating to 0 and during this time, there is an overshoot on the DC voltage

Then after 0.5s, the motor accelerate as expected.

The offset calculation is not enabled.

I have in mind something like if the current regulator setpoint is not correctly set.

I try to increase the flying start delay but it just delay the time when the motor accelerate, the overshoot is the same.

Can you help me to reduce this overvoltage?

With best regards