Here is our recommendation for developing with InstaSPIN

Assuming you have already used the InstaSPIN website, the InstaSPIN simulation, and read through the Technical Reference Manuals (links on website)

to convince yourself that InstaSPIN-FOC and/or -MOTION are the right solution for you...

- Purchase an evalution kit

- TMDSHVMTRINSPIN

- includes TMDSCNCD28069MISO and TMDSCNCD28027F controlCARDs

- DRV8301-69M-KIT

- includes TMDSCNCD28069MISO

- you can purchase separately TMDSCNCD28027F which also requires the use of an external emulator (your choice: XDS100V2, XDS510, isolation recommended)

- DRV8312-69M-KIT

- includes TMDSCNCD28069MISO

- you can purchase separately TMDSCNCD28027F which also requires the use of an external emulator (your choice: XDS100V2, XDS510, isolation recommended)

- LAUNCHXL-F28027F + BOOSTXL-DRV8301

- Isolated XDS100v2 LaunchPad with InstaSPIN-FOC enabled TMS320F28027F

- BoosterPack for 6-24V, 10A continuous three phase motors

- LAUNCHXL-F28069M + BOOSTXL-DRV8301

- Isolated XDS100v2 LaunchPad with InstaSPIN-FOC and -MOTION enabled TMS320F28069M

- BoosterPack for 6-24V, 10A continuous three phase motors

- TMDSHVMTRINSPIN

- Install latest version of www.ti.com/tool/motorware

- Run MotorWare.ex from the install location, ex: C:\ti\motorware\MotorWare_1_01_00_11\MotorWare.exe

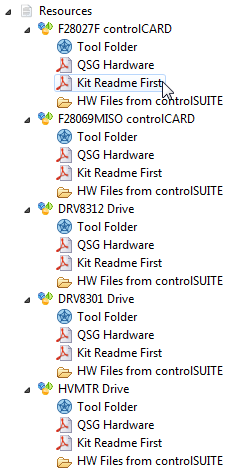

- Each kit which includes a 69M devices has a CD with "kit contents". The latest version of these kit contents is always here. The 27F and Launchpad based kits have Universal GUI support with latest version always here.

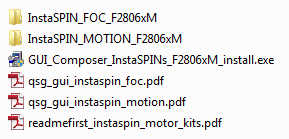

- Download and unzip this file and note the contents:

- Read and follow "readmefirst_instaspin_motor_kits.pdf"

- This document is also included in MotorWare.exe, linked with every piece of hardware.

- Also note the location of the QSG Hardware document for each piece of hardware, these should be reviewed as you set-up the kits

- The hardware design files are kept in controlSUITE (C2000 MCU main product support) to keep the MotorWare installation smaller. Install controlSUITE if you want to access these files.

- If any confusion, view the Getting Started video

GUI Evaluation

- Follow the "qsg_gui_instaspin_foc.pdf" or "_motion.pdf" or "qsg_gui_universal.pdf"

- This includes running the GUI Composer installer which installs the standalone run-time

- If needed, view the GUI training videos

- InstaSPIN-FOC GUI Overview

- InstaSPIN-MOTION GUI Overview

- InstaSPIN-FOC LaunchPad and BoosterPack (Universal GUI) Series

Evaluate the MotorWare projects and start learning about the software architecture, code structure, and API interface

- install the latest version of CCStudio from the included DVD or from the wiki site.

- Ensure that you are using compiler 6.2.3 or newer. There is a MAJOR BUG in compilers 6.2.0-6.2.2 DO NOT USE

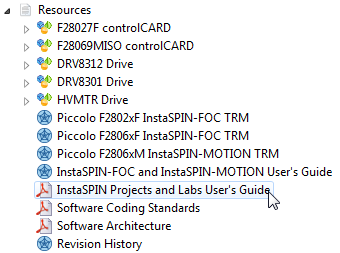

- Follow the Projects & Lab User's Guide in MotorWare.exe

- CCS notes

- Be sure that when you import the projects you do NOT select "Copy projects into workspace" option. We recommend working out of the MotorWare installation directory. This will make it much simpler to keep up with future revisions.

- Do NOT change any of the project settings. Ex: you do NOT need to change the General --> Variant option to a specific device. This just selects a pre-installed .cmd file that will NOT work with the MotorWare projects. The .cmd files included in MotorWare are already attached to the projects.

- The general path for using CCS and MotorWare projects

- Import projects

- Make changes to user.h or the project .c as required

- Build selected project

- Set-up Target Configuration (emulator and device)

- XDS100v2 + F28069 (all kits)

- XDS100v1 + F28027 (HVMTR kit)

- XDS100v2 + F28027 (LaunchPad)

- your emulator + F28027 (DRV kits)

- Launch Target Configuration

- Connect Target

- Load Program you built in 3.

- Turn on real-time debug

- Run

- Set-up Expressions View using the .js file for that project

- Interface to software using Expressions

- Starting in release _10 you can also use new Universal GUI inside CCS to instrument variable

- As you work through the labs, consult the appropriate sections of the InstaSPIN-FOC & -MOTION User's Guide for further details

- Ex: when working through lab 2 you will want to review the Motor Identification chapter of the UG to understand exactly what is happening and the options you have to make changes.

- If you want to start your own project based on a MotorWare example, a method for doing so that allows portability as we release new revisions (~2-4 times per year planned) is outlined in this post.

After evaluation and initial software development, prepare your own hardware

- Be sure to follow the guidance in the User's Guide regarding analog sense circuitry design