I have been playing around with motoware on the LAUNCHXL-F28027F + BOOSTXL-DRV8301 platform for a while now. For the most part I am coming to terms with it. However I am left with several questions I haven't been able to solve to my satifaction.

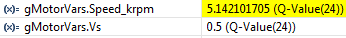

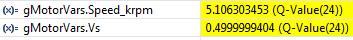

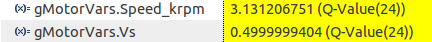

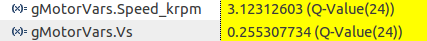

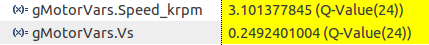

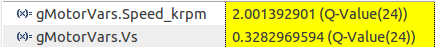

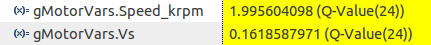

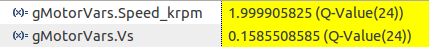

How do I add overmodulation to lab11? The lab notes say it is the same as lab 10a, but lab10a also uses the CTRL object. I copied runCurrentIgnore, runCurrentReconstruction, and runSetTrigger from 11a. I also copied the relevant svgencurrentHandle, etc initializations. The motor runs, but the results are kind of odd. In lab10 I can acheive ~3900rpm with modulation set to 0.67 and ~3100rpm with modultion of 0.5. In lab11, with all my additions commented out and USER_MAX_VS_MAG_PU =0.5 I can still reach 3900rpm, shouldn't it only be 3100?

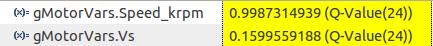

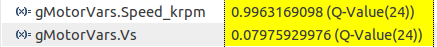

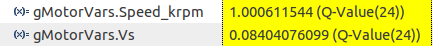

Is there a reccomended way to add stall detection? I'm thinking of the case where foriegn objects cause the rotor to lock and the motor needs to be shut down to prevent damage. I noticed when I lock the shaft, speed estimates of ~1krpm are returned in most cases. My current techniques is to declare a stall when est. rpm is <1.5k and reference rpm is >2.5krpm for > 1 second. In the case where ref rpm is <2.5k I declare stall if current is >5A for more than 1 second. Is there a more elegant way? This is for a fan application.

The motor/controller will need to be tested with the fan removed, but this will wreak havok when used with the high gains required for the fan, the motor will oscillate and be very noisy. Is there a way to detect the presence of the fan inertia? Current on startup maybe? Any other suggestions for how to solve this problem?

Is there a way to selectively optimize files in the motorware projects? I noticed by default the debug level is 2, this make actually debugging anything quite a challenge. If I set optimization to 0 the code is either too large or doesn't run. I would like to be able to optimize most of the files, but leave the ones I am working on at -o0.

Should Is_A match up with the measured input current? I had to increase USER_IQ_FULL_SCALE_CURRENT_A to 25 for my motor to reach full power. When testing at full power Is_A shows >20A, but my power supply shows like 18A.

That's all I have for now. Thanks in advance for the help.