Hi,

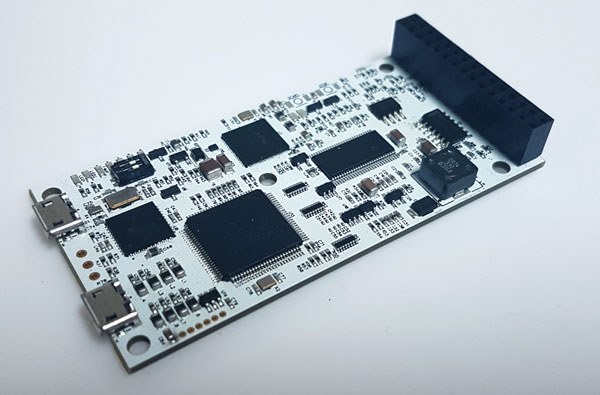

We have used your schematic for the DRV8301-69M-KIT, to create a smaller version with the same functionality. It is a complete copy from this schematic but with other mosfets, IRFH7004TRPBF. The layout is however competely remade. We are using two pcb:s stacked over each other. Where one is the power-PCB with mosfets and current sensing resistors and the other PCB contains all the signalling and logic hardware. But after 5 revisions and countless checks of hardware and comparision with the original design, we still have issues with getting everything to run well. We can program the F28069M with no problems and also run the laborations. Allthough here is where the problems appear. When running laboration 7c from your MotorWare library with the evaluation-kit DRV8301-69M-KIT, we have no issues and the motor is running very well. But using our own layout based on this design, the motor starts jumping very hard in the progress of identifying the motor, almost like every third phase. It can start turning but uses way to much current and gets very warm. We have made all checks against schematics and have found no error, so we are leaning towards some kind of design issue. But we have no idea of where it might appear in our hardware. The pcb:s are created using Diptrace, but we can export to numerous format and are happy to share the design with you if you have possibility to look it through. We are stranded a bit here.

Do you have any recommendation on where to look for problems and what we can do to get forward. This is a vital project for us and the driver is intended for long term underwater autonomous vehicle as a part of one of the most critical systems on board. We love how it performs on the evaluation kit, but we have no space for this in the final mechanical design.

Best regards,

Mikael