Other Parts Discussed in Thread: TMS320F280049C, , C2000WARE, BOOSTXL-DRV8320RS, OPA2350, AMC1300

Hello team,

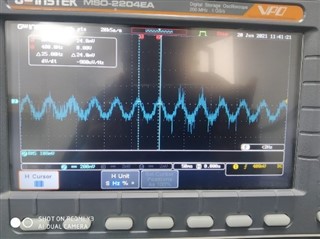

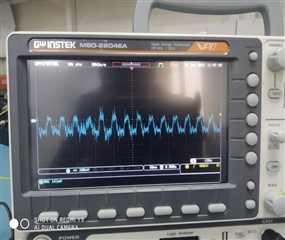

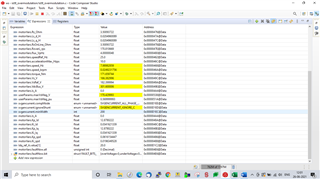

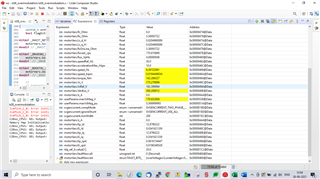

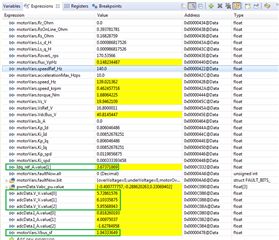

We are using TMDSHVMTRINSPIN + TMS320F280049C, earlier we could control the motor without load, by flashing the codes presented ‘C:\ti\c2000\C2000Ware_MotorControl_SDK_3_00_01_00\solutions\tmdshvmtrinspin\f28004x\ccs\sensorless_foc ".for speed controlling we are using lab07.

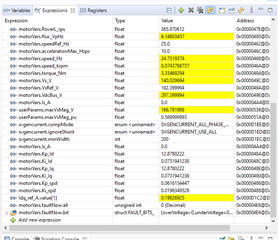

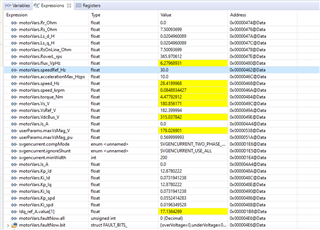

1. Now we are going to test my motor with load, below are my motor parameters

Rs: 6.5ohm

Ld: 0.010496

Lq: 0.010496

Pole pains: 20

Rated Torque: 230 N-m

Output power: 1.4 KW

2.Is TMDSHVMTRINSPIN that board support to test my motor with full load?

My application is HVLS fan

FYI: we are using lab05 for motor parameters identification, we don’t have any problem without load condition. we get correct parameters.

thank you