Tool/software: Code Composer Studio

Hello

I want to use delta-sigma module to read the current in a PMSM drive. I am using TMS28F377D with AMC1305 delta-sigma modulator.

I am not expert and I am confused a little with the TRM section of delta-sigma!

I want to measure the current exactly in the beginning of my sampling period (Ts=50us). As I noticed, by using S-D module, an average value of current is achieved. The period of average is defined by "Latency of Sinc filter" (correct me if I am wrong).

Is it possible to reduce this period to about 1us? How should I adjust the SINC order and OSR for this purpose?

Other point is that as I have understand, there is duration in

which wrong data is sent by AMC1305 (tISTART in datasheet of AMC) and read by DSP (table 12-4 in TRM). Are this wrong data repeated in every time (every sampling time) I read the current from AMC ? if "yes", I think this may limit my minimum "Latency of Sinc filter". Is it true?

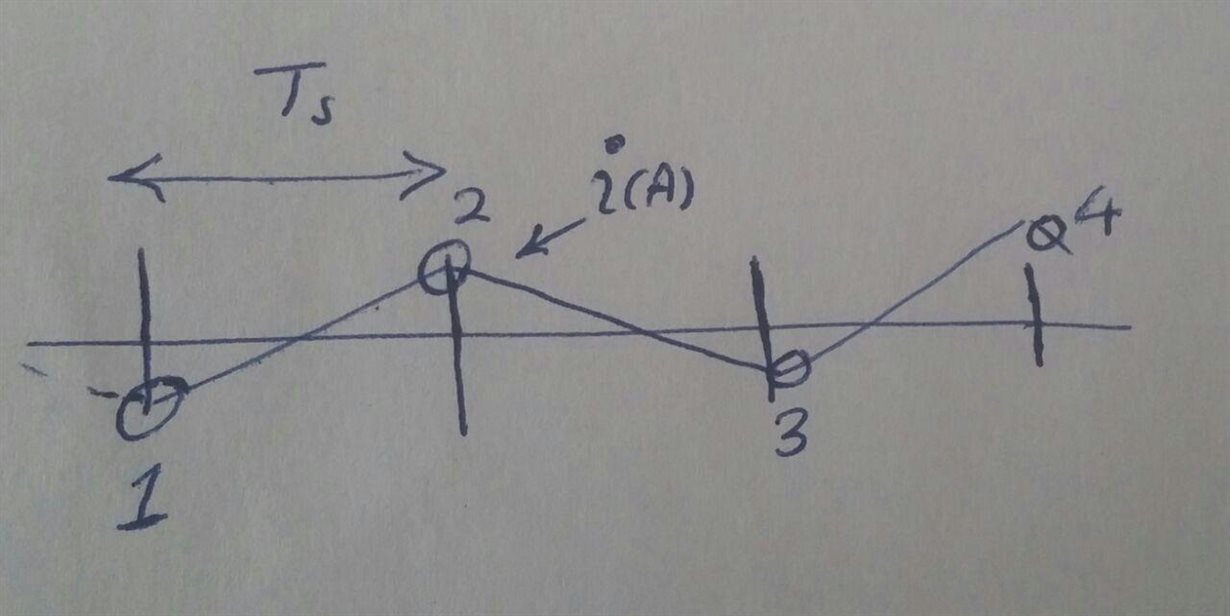

Please guide me how could I read the current in the beginning of every sampling time (Ts=50us) and only in a maximum duration of 1us . In fact I want to measure the current in the numbered time instances of the attached figure to estimate the torque of the motor and control it in a predictive manner.

regards