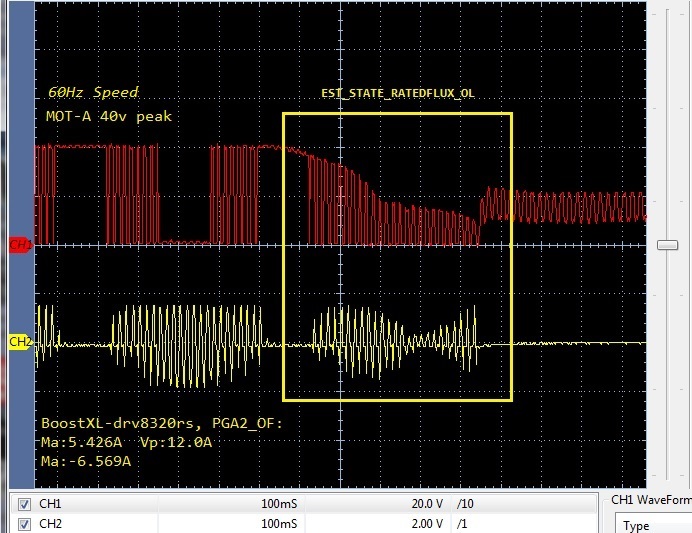

Testing BootXL-DRV8320rs with full CMPSS DC bidirectional current protection engaged to keep rotor moving, until unsafe current conditions.

The PWM droops DC power supply as EST_STATE_RATEDFLUX_OL starts up after constant speed and current ramp stabilizes.

2. Dumb question being should CH1 voltage drop on purpose or is the current load to much for the state to finish?

3. If it should not drop voltage (yellow box) then how does reduced current CH2 cause sudden DC trip zone fault?

4. How on earth did motor ID=true @20Hz with rotor stalled, then run without error for online lab5? Not so important unless the DC comparators are working as they should and ID process Rated_Flux step trips OC faults at 20Hz.

5. Why do the user parameters entered into user.h not accelerate the rotor in lab 5 when launched with use user.h parameters flag = true? All that occurs is the rotor slowly rolls clock wise as if the trajectory target speed parameter is missing. This happens on boostXL and our custom DC inverter and it seems SDK requires certain parameter values gathered during motor ID process that go missing when CCS debug secession ends. Lab 13 has the same behavior and only accelerates the rotor up to target Hz after motor ID=true after lab5 enters OnLine state. Seemingly the SDK should save a lot more than user.h motor vars in a flash parameter block for later debug sessions. Lab 5 is loaded into flash memory as instructed via lab user guide.

I plead totally bamboozled by this behavior, lol. Be safe and keep some distance from others!