Other Parts Discussed in Thread: C2000WARE-MOTORCONTROL-SDK

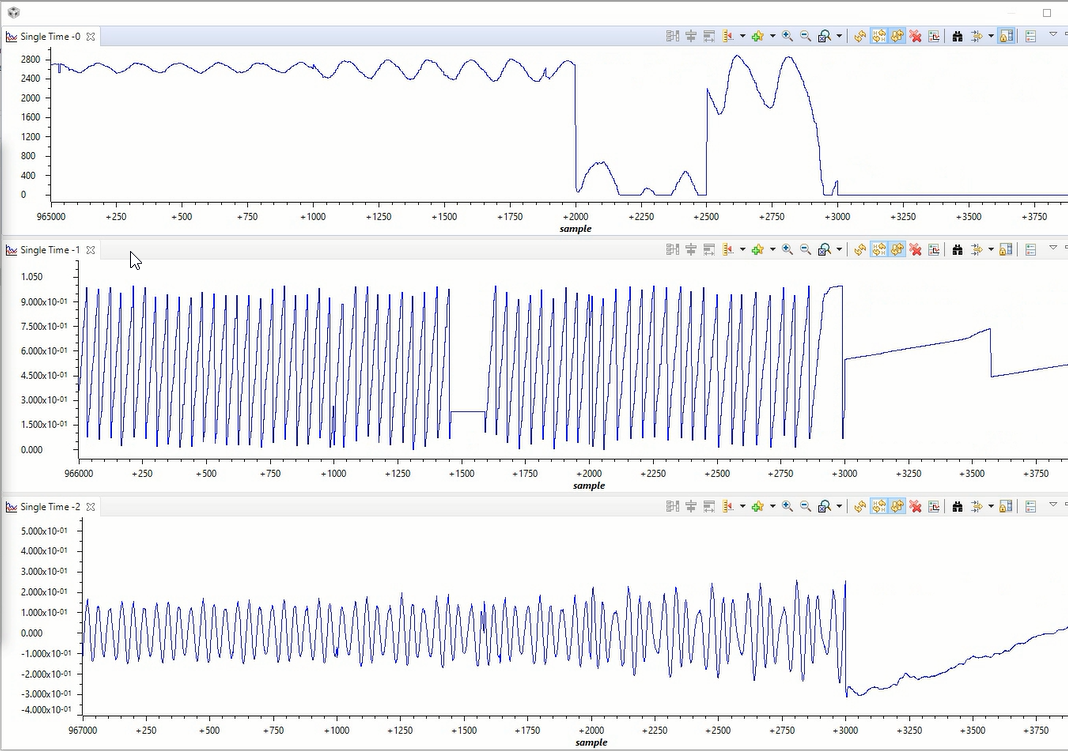

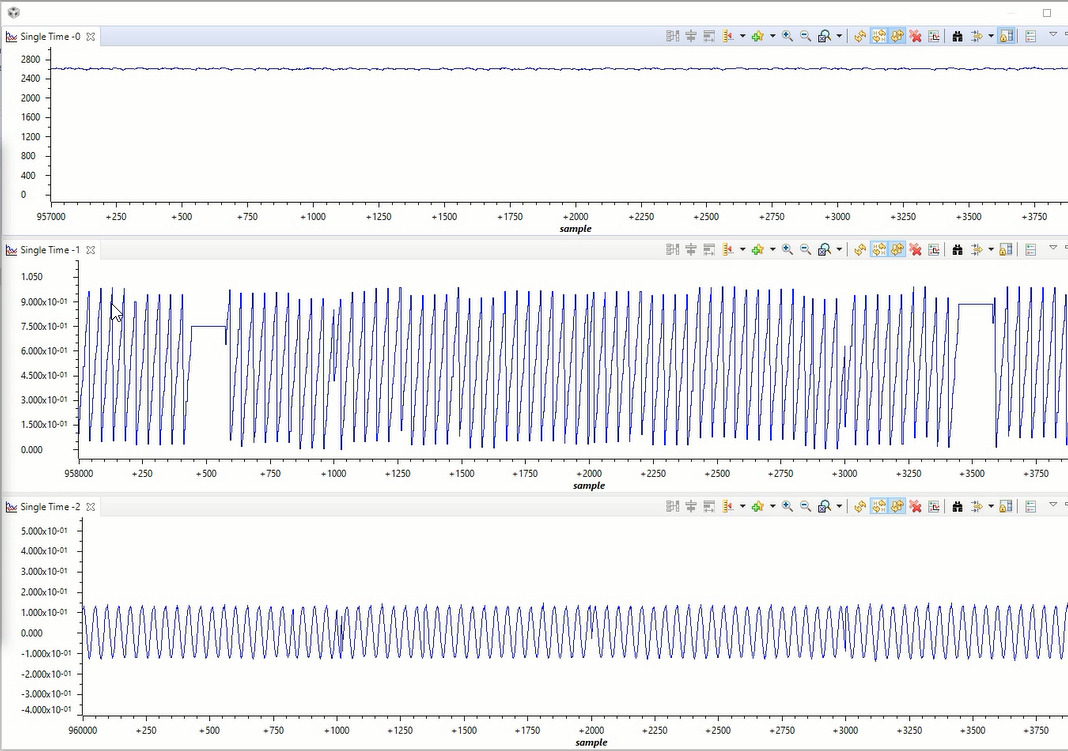

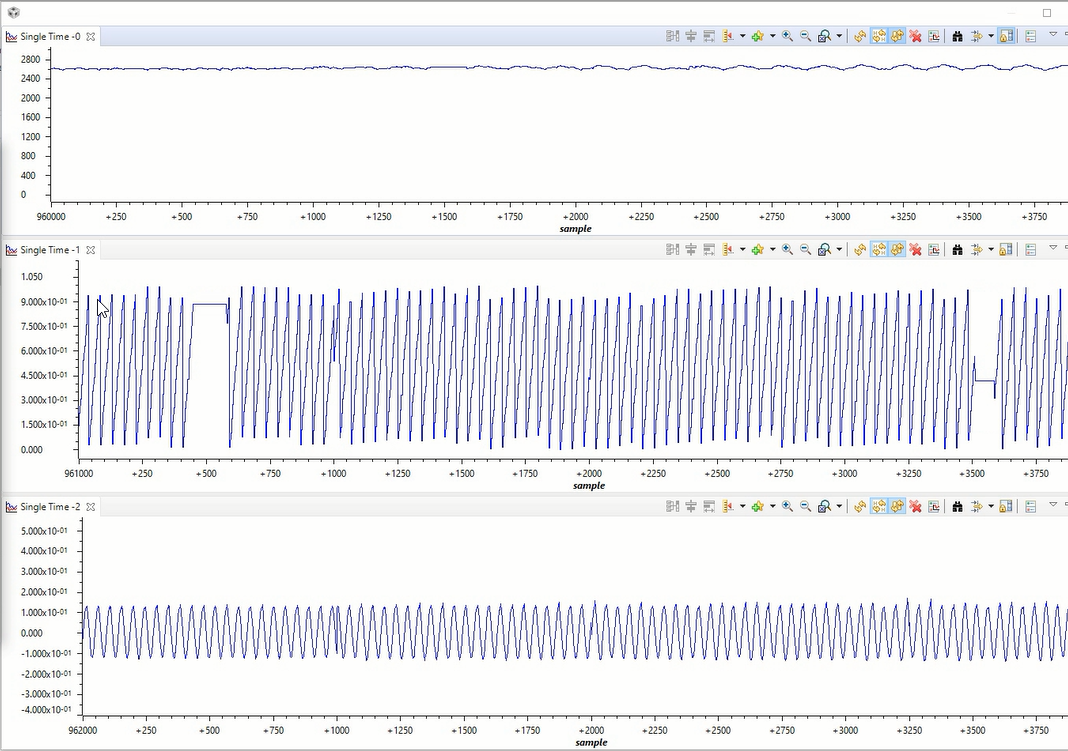

I am working on confidential custom hardware, VFD of 3.7kW rating in which TMS320F28062F is used. Application has been developed using Instaspin labs provided, which is able to run the SPMSM motor without any issue, I am facing problem with the IPMSM type of motor wherein at the particular frequency the motor is vibrating a lot. Let me know if any further specific information is required. Please suggest a solution.

Samir