Other Parts Discussed in Thread: DRV8320, BOOSTXL-DRV8320RS, EK-TM4C1294XL, INA240, OPA2350, TMDXIDDK379D, , UCC27714, TIDA-00778, MOTORWARE, DRV8301, TMS320F28027F, DRV8305

Hello all,

I recently design 22 pole PM rotor out of scrap parts to use on 24 tooth custom stator, 300mΩ each of 3 phases Star winding. Rotor has some minor cogging but easily rotates over each slot by hand push, initial slot being the hardest. Oddly 6 step trapezoidal FOC sensorless open commutation controller only rock rotor +/-5° 1A up to >8A , 40v to 170v. This cogging torque is well known in RC car groups as delay startup and the KV controllers somehow overcome cogging. Yet FEM analysis without stator skew show cogging torque roughly +/-400-600mNm and we know adding any slot skew reduce that even more.

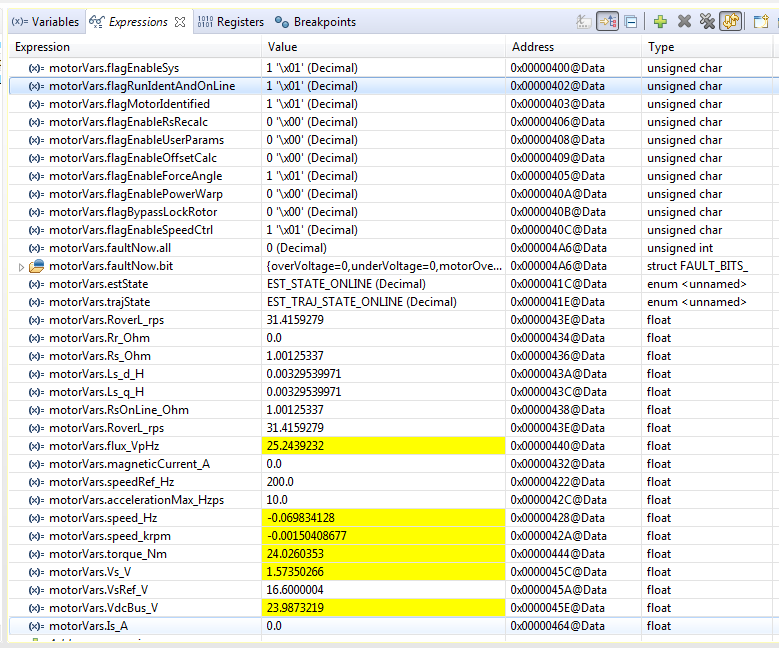

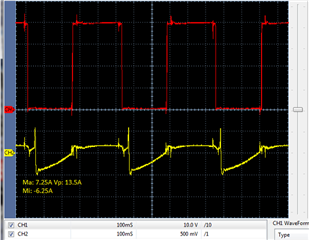

Will space vector FAST and SDK motion spin or even push most typical RC cogging rotor over the first slot? Oddly the non-powered scope capture of two phases is not single sine wave and more of a stepped sinusoidal pattern, perhaps due to the laminations skew angle that changes nearly every 60°. I would classify motor as 22 pole BLDC since SPM has pure sinusoidal wave form when human hand rotates rotor.