Hello,

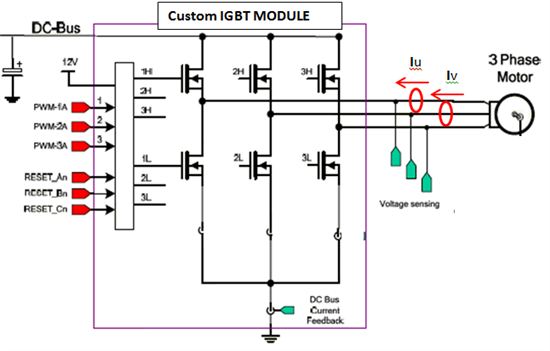

What are the InstaSPIN-FOC requirements on the current feedback sensors in case of the hall effect type?

I've read a lot about the ideal sampling windows for current sensing with shunt resistors, 2 or 3 shunts, op-amp slew rate for each case.. Could you please post some recommendations for the hall-effect sensors?

I already saw LEM manufacturer mentioned somewhere here, but I couldn't find any info on the actual bandwidth needed for the correct current sensing. Should the bandwidth match the PWM frequency? Is op-amp like AD8226 with a slew rate around 0.4 V/us fast enough? Since those sensors does not have an infinite bandwidth, would you recommend a filter to remove high frequency (noisy environment, long cables..)?

Thank you.