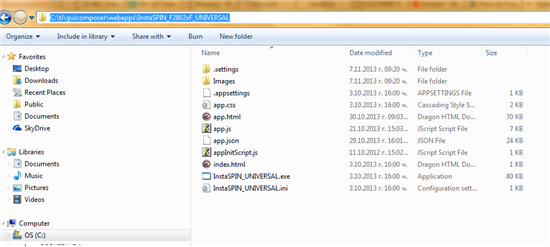

OK, so I have this kit and have lunched both controlsuite and motorware. BOTH! do not work as they state "C:ti/guicomposer/webapps/instaspin_f2802xf....." not found. There is in fact NO suck directory or file so of course it is going to fail!

I don't want to "develop" anything at the moment! I just want to spin a BLDC motor to do some engineering tests!

What in the world do I need to do to get this thing to run? The instructions are as useless as this Kit is at the moment, as it just instructs me to download instaspin (which I did) and the damn thing still does not want to launch or run anything.

Yes I am frustrated. You would be too after spending $800 on your kits that don't do a damn thing!