Other Parts Discussed in Thread: LMT01, LMT01-Q1

Hi,

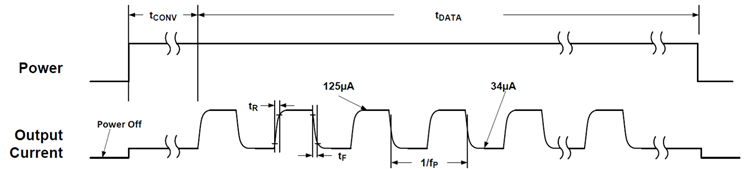

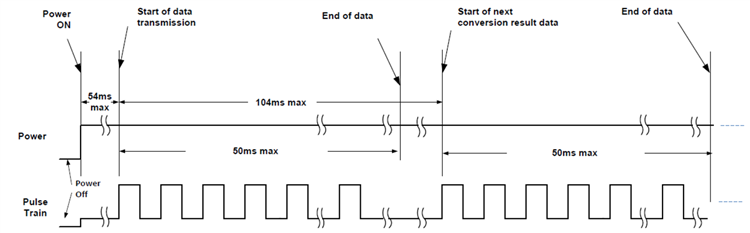

I need to do some temperature measurements in a high noise environment where an NTC just wont do. And it needs to be small, cheap and automotive qualified...because somebody out there hates me, personally. I was looking at the LMT01 which would fit my requirements but I am not sure how to properly capture the data with my C2000. The LMT01 puts out pulses at 88kHz. You switch on the supply and after 54 ms it starts to put out pulses at 88 kHz for up to 50 ms. The number of pulses indicates the temperature.

In an MSP430 I would place a comparator on the output, enable the internal filter with a 5µs filter duration in the comparator to prevent noise from being counted as a pulse and then wire the comparator output as clock into a timer. Reset the timer at start, check the timer count register (equivalent to the number of "clock" pulses that came in), do the conversion, done.

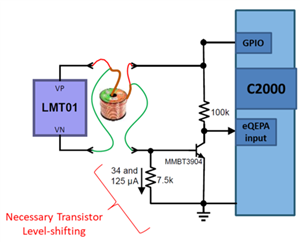

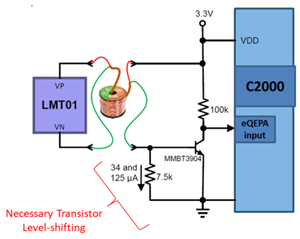

How do I do that in the C2000? Running interrupts every 10µs for up to 34 ms is not an option and I need to distinguish between real pulses (>5 µs) and noise pulses (ballpark 50-100ns). I assume wiring the comparator output into the CLB through the X-Bar would be an option but I don't have CLB experience or the right tools set up.

BR and Thanks

Peter