Other Parts Discussed in Thread: MSP430WARE, MSP-TS430PZ100AUSB, MSP430FR2355

Hi Gurus,

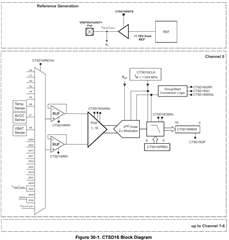

We use an MSP430FG6426 for the CTSD16, to measure a few voltages. We are trying to establish from first principles what is the input voltage range. And by the looks of it we can not even reliably measure the the internal temperature with the example codes.

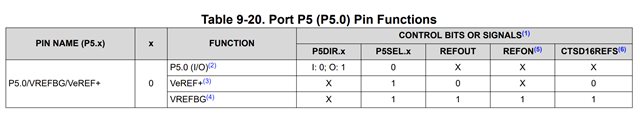

On our board we are using single ended inputs and P5.0 is through a 1nF cap connected to AVSS. And no internally programmed gain.

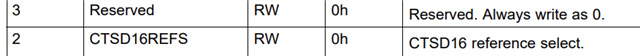

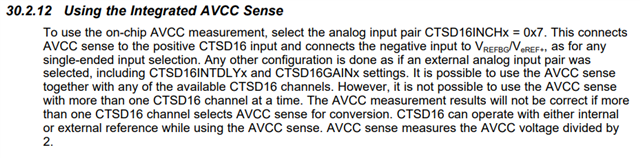

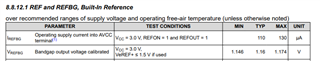

What is the reference voltage? According to various places in the datasheet and the programming guide (www.ti.com/.../slau208q.pdf) there is mention of VEREF in module 26.

There is mention that P5SEL should be set to 1, while setting in REFCTL: REFON, REFOUT, REFMSTR. But there are some confusing statements that the VEREF module can change the reference voltage

Wed didn't know about the P5SEL for a while, so we've never set it, and it never seems to have any impact what's happening.

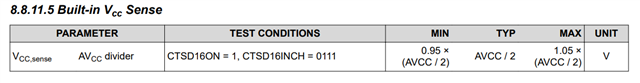

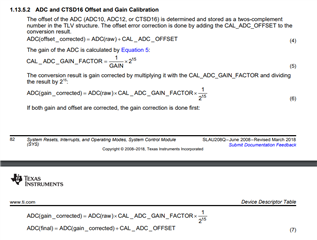

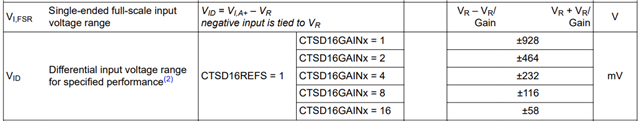

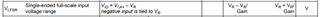

So the ultimate question is if the reference voltage is a fixed 1.16V, then what is the voltage range for a single ended input? 2.32V? If so how do you map the 16bit MSB (I guess independent of the oversampling rate) to voltage values? (With 2's complements)

I apply 100mV (above AVSS), what is the expected CTSD16MEM0 content? Assume LSBACC=0.

100mV/2320mV * 32768 = 1412?

Why is there a different full scale range and a specified performance range?

-----------------

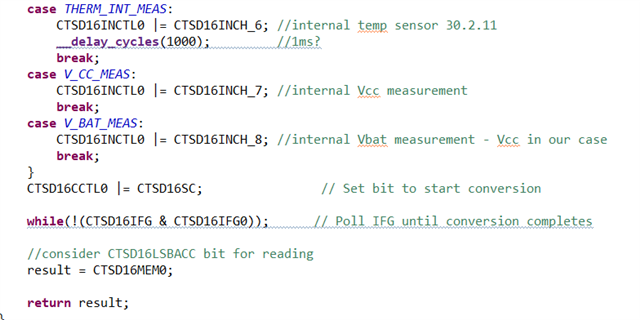

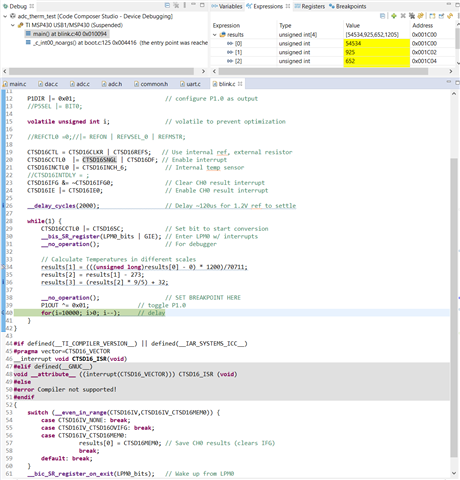

The below code is almost identical to msp430fg662x_ctsd16_06.c in c:\ti\msp430ware_3_80_14_01\examples\devices\MSP430F5xx_6xx\MSP430FG662x_MSP430FG642x_Code_Examples\C\ Only added a little bit of LED blinking.

The below code is run by wiring an MSP430FR2355 Launchpad to the MSP-TS430PZ100AUSB Launchpad. Obviously we only use the former for debugging capability. By looking at the latter's schematics it is not grounded through a 1nF cap, but a 100nF and a 10uF. The two boards are connected through SBWTDIO/TCK.

You can see it below as I stopped the debugger that the temperature is calculated to be 925Kelvin, which is obviously incorrect. Power cycling the board sometimes yields a totally different number.

Any ideas what is happening and why this would not be working?

Thanks for your help!

Peter

, so with no gain you will have from 0 to 2x the reference (which is 2.32V)

, so with no gain you will have from 0 to 2x the reference (which is 2.32V)