Hi,

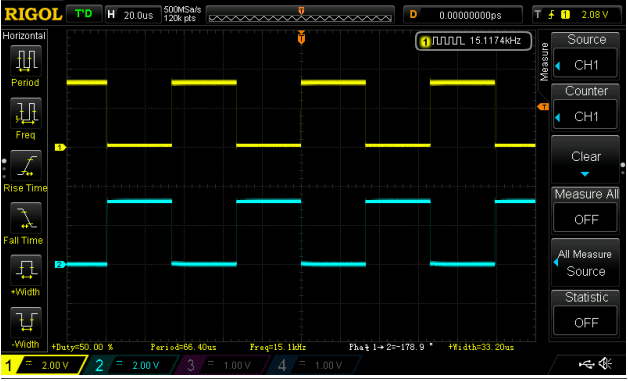

How to create two PWM signal with 180 degree phase shift.

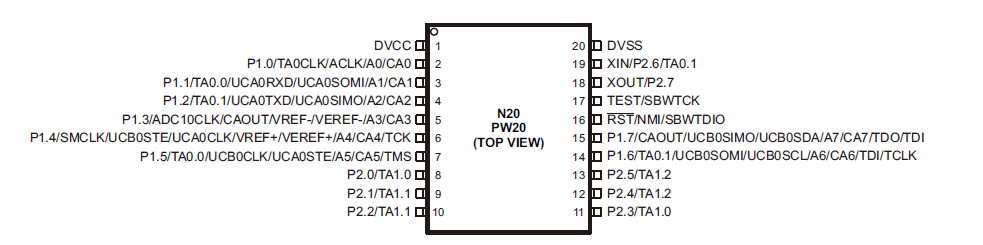

MSP430G2553 has two timer TIMER_A0 and TIMER_A1 with three capture and compare register.

Is it possible with MSP430G2553 and if yes, what is the solution for this?

Please help me to understand the logic along with the code..

Thank you in advance..!!