Other Parts Discussed in Thread: MSP-TS430RGZ48B

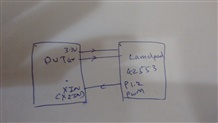

I conducted EFT on the above mentioned device and it fails at a pulse of 500V only when an external crystal is connected, but if I run the test on device (working on internal crystal) with 4KV pulse the device runs ok.

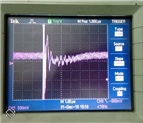

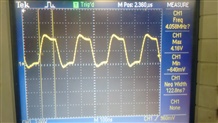

1) Is the PLL section of the device which is being affected? I see a glitch in oscillation of crystal during noise pulse and then the crystal oscillations stabilizes(during absence of noise pulse): this cycle repeats as noise pulses are running and eventually the MSP gets hanged. Is there any solution for it??

2) If I use KC5032A16.000CM0E00 as an external oscillator at 3.3V instead of crystal, will it solve my problem? And if I were to use it then how can I configure MSP for an external clock source?

3) If the above mentioned oscillator also won't solve my problem and if i were to use internal crystal (in a temperature range of -20 to 80 degree Celsius) how should I compensate the temperature drift on UART baudrate (as the DCO frequency drifts as temperature changes)?