[ MSP430F2112 ] Possible Failure Caused by Segment A Erase

Hi,

Can you help my customer to debug their issue found on their own board with MSP430F2112?

My customer has reported that MSP430 shows unstable operation and malfunction.

From discussion with customer, we have found that the Segment A is erased, all FFs.

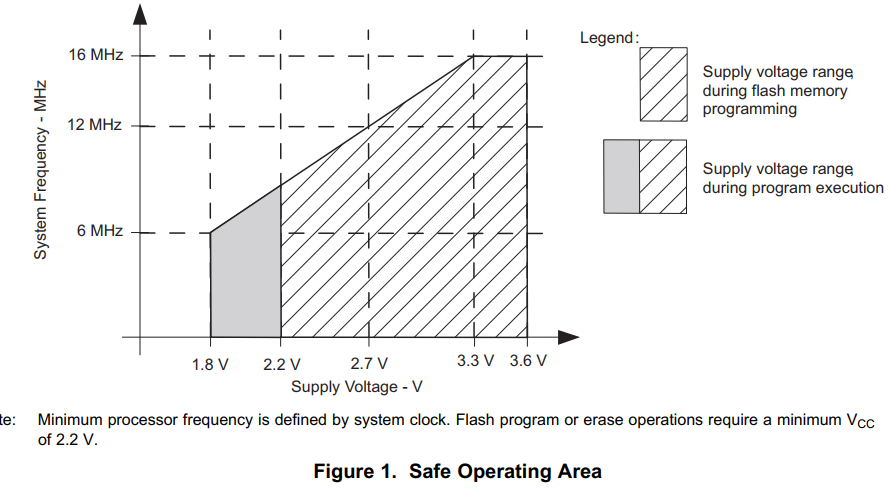

As our understanding, if Segment A is erased, the processor frequency cannot be set correctly, and let MSP430 run under out of range eventually.

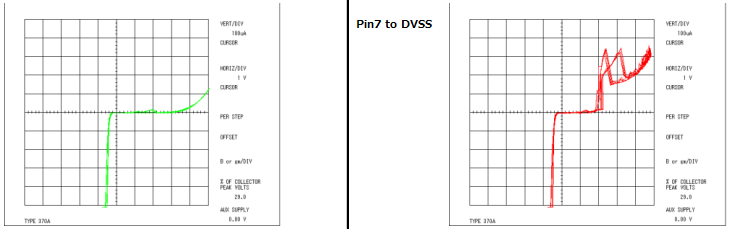

Also, we have received some failure units from customer and performed curve trace analysis.

The result shows that failure units have slightly different V/I characteristics on pin 7 (RST/NMI/SBWTDIO) compare with known good device.

Do you think Segment A erase cause this kind of failure?

Thanks,

Ken

<Related Post>:

MSP430F2112: BCM initialization: Setting fCPU=16MHz

e2e.ti.com/.../662987