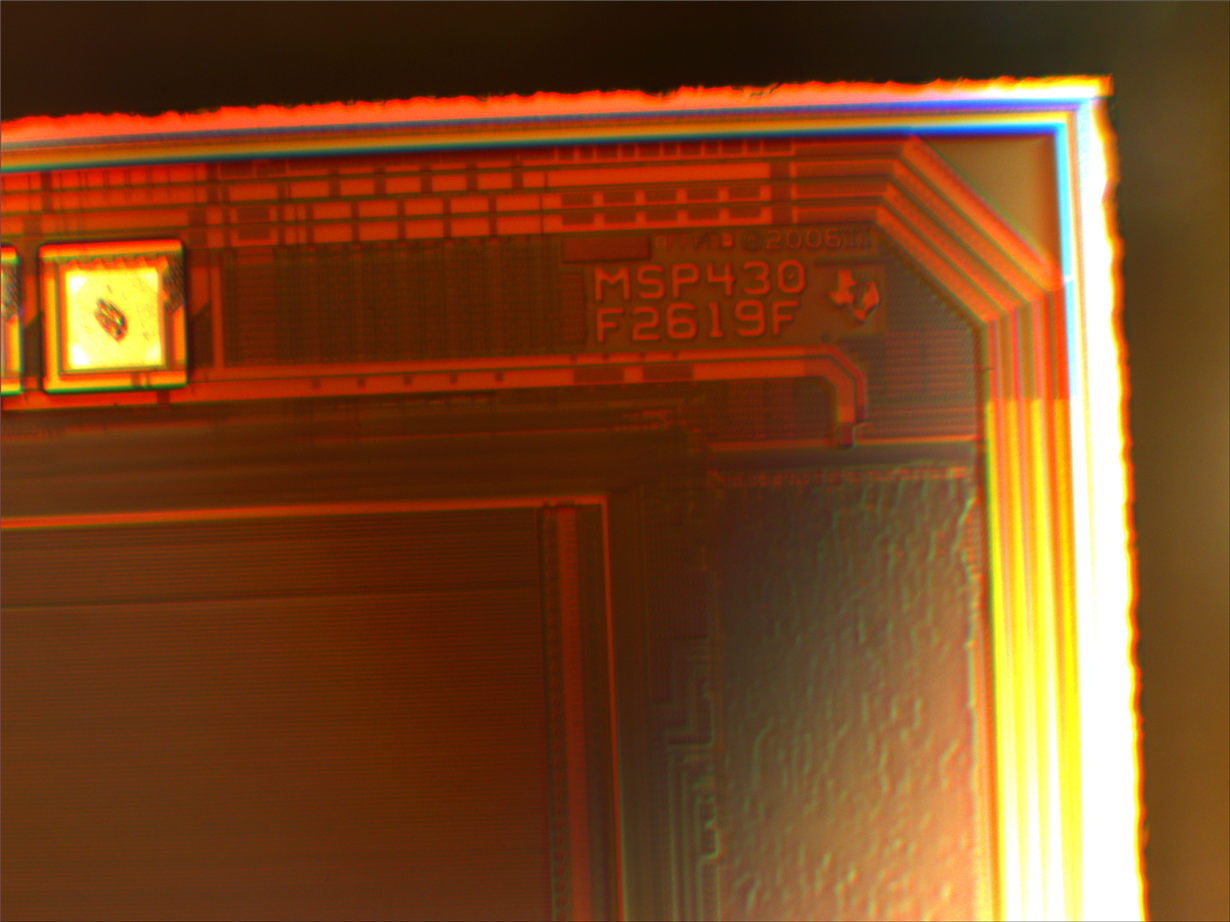

Other Parts Discussed in Thread: MSP430F2619, UNIFLASH, MSP-FET

Hello,

I have some new MSP430F2619 microcontrollers. So far, each one has had a blank Segment A, which is used for clock timing. As I understand it, the MCUs are calibrated at the factory so the clocks are accurate over their specified temperature range, and this calibration information is stored in Segment A.

I have some Segment A calibration coefficients from other chips, and I've tried loading those on to these new ones. Some work, some don't, but there isn't a way to know if those other coefficients would work over the whole temperature range.

Is there a way to manually calibrate these chips?