Other Parts Discussed in Thread: CC2650, TIDM-BLE-REEDMTR,

Hello MSP Team,

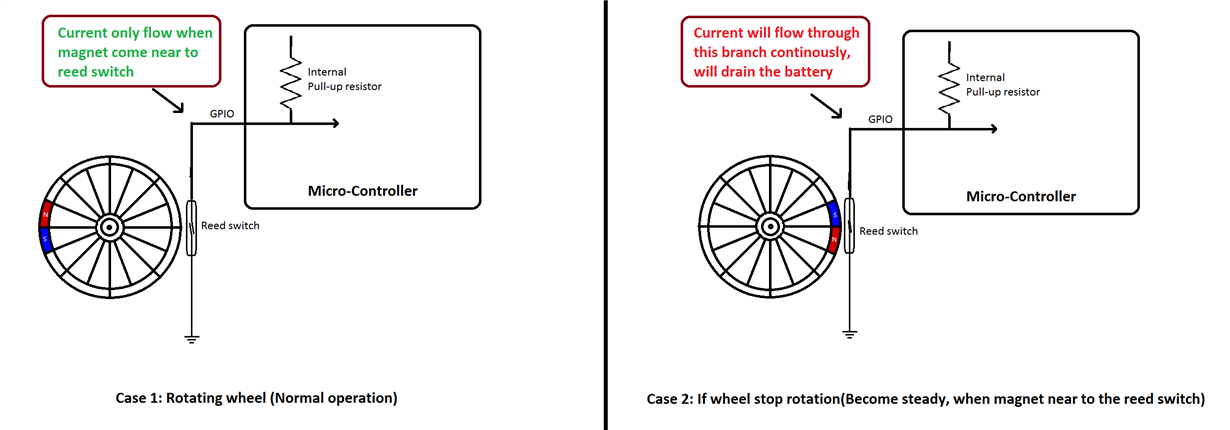

Need your inputs on this. Our customer is into a battery-operated flow measurement application using a meter. This meter has a magnet attached to a wheel, which is then detected by the system using a reed switch. However, they're having issues when the meter wheel magnet asserts the reed switch; it remains on this condition leading to the GPIO being pulled low and causing increased current consumption even at sleep mode.

We've tried proposing TIDM-BLE-REEDMTR as solution - utilizing the sensor controller engine of CC2650 for the interrupts. However, they're quite restricted in using MSP430F437 for this application.

Can you advise on any hardware/software solution for implementing this in MSP430F437?

In case you need more information, please let me know. Thank you for your support.

Kind Regards,

Jejomar