Other Parts Discussed in Thread: TIDM-1021, , CAPTIVATE-PGMR, MSP430FR2522

Hello everyone,

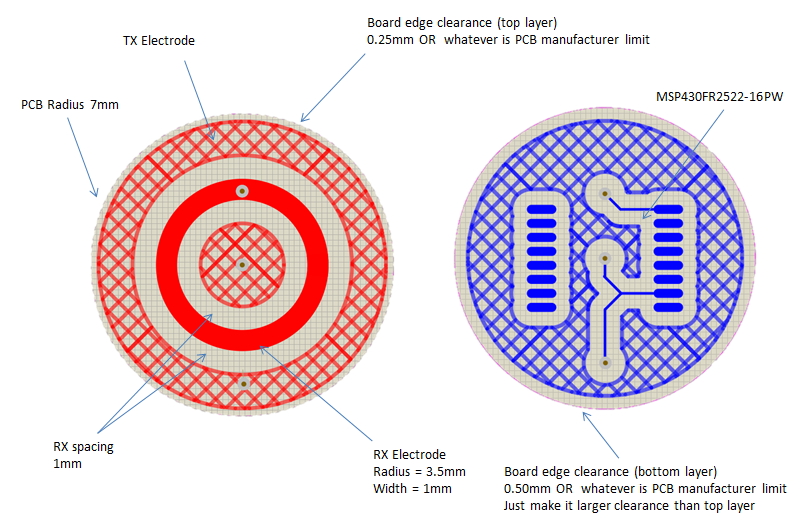

my goal is to develop a waterproof capacitive touch-sensor.

In many sources on the internet, it is said that a mutual-capacitance sensor can achieve this.

For example, in the TI Designs: TIDM-1021 Liquid Tolerant Capacitive Touch Keypad Design application note: https://www.ti.com/lit/ug/tidue90/tidue90.pdf?ts=1598517326899&ref_url=https%253A%252F%252Fwww.ti.com%252Ftool%252FTIDM-1021

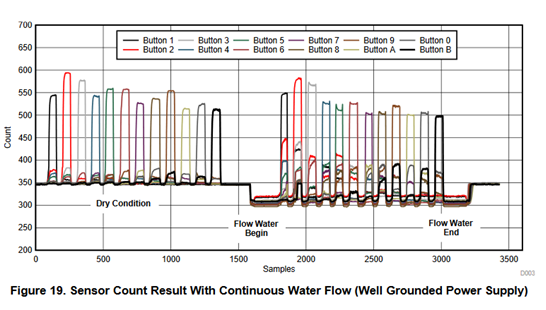

We can read page 5: "The increase of Cmutual causes the measurement result to go in the opposite direction of a touch, and this opposite result is called a "negative touch". This "negative touch" behavior helps to prevent false touch detection when liquid is present."

This phenomenon is also illustrated figure 19 on page 18.

As the TIDM-1021 part is no longer available, we are using a similar part which is the BOOSTXL-CAPKEYPAD. It also works with mutual-capacitance sensing, hence we expect to achieve the same results.

However, it does not work: water on the sensor causes the mutual capacitance to decrease and hence causes the measurement result to go in the same direction of a touch. No "negative touch" is present and hence we cannot prevent false touch detection due to water.

We use the CapTIvateDesignCenter to monitor the measurement result. Here is what we get:

First we a dry touch:

And then with a water drop:

The idle state of the signal lies at the +400 level. As you can see, the effect of water drop is weaker than the effect of a dry touch, but still goes in the same direction (an increase of the measurement signal, meaning a decrease of the mutual-capacitance).

In our setup, we are using:

- the BOOSTXL-CAPKEYPAD,

- the CAPTIVATE-PGMR to program the board and monitoring signals on our computer. It also powers the board from the USB-bus.

In the application note, they also use a CAPTIVATE-ISO but it is written that if the system is powered from the host PC, there is no need for the CAPTIVATE-ISO board. So it seems OK. Our power supply is then not grounded to earth ground, but page 11 specifies that it has an influence on sensitivity only (which is not the issue in our case).

Something seems interesting on page 5: "The amount of grounding path around the sensors. Liquid couples the sensor to larger grounding path reduces the mutual capacitance and causes the measurement result to go the same direction as a touch." But I don't really understand what it means and what can we do about it.

Thank you for any help about this issue.