Part Number: MSP-CAPT-FR2633

Hi,

I am currently using the CapTIvate design guide to design my own capacitive touch PCB. It is indicated in the design guide that the digital LED signals should always be at least 4 mm from the capacitive touch pads and tracks. Though it seems unclear whether the 4mm rule applies to just tracks on the same layer or also if tracks are on a different layer.

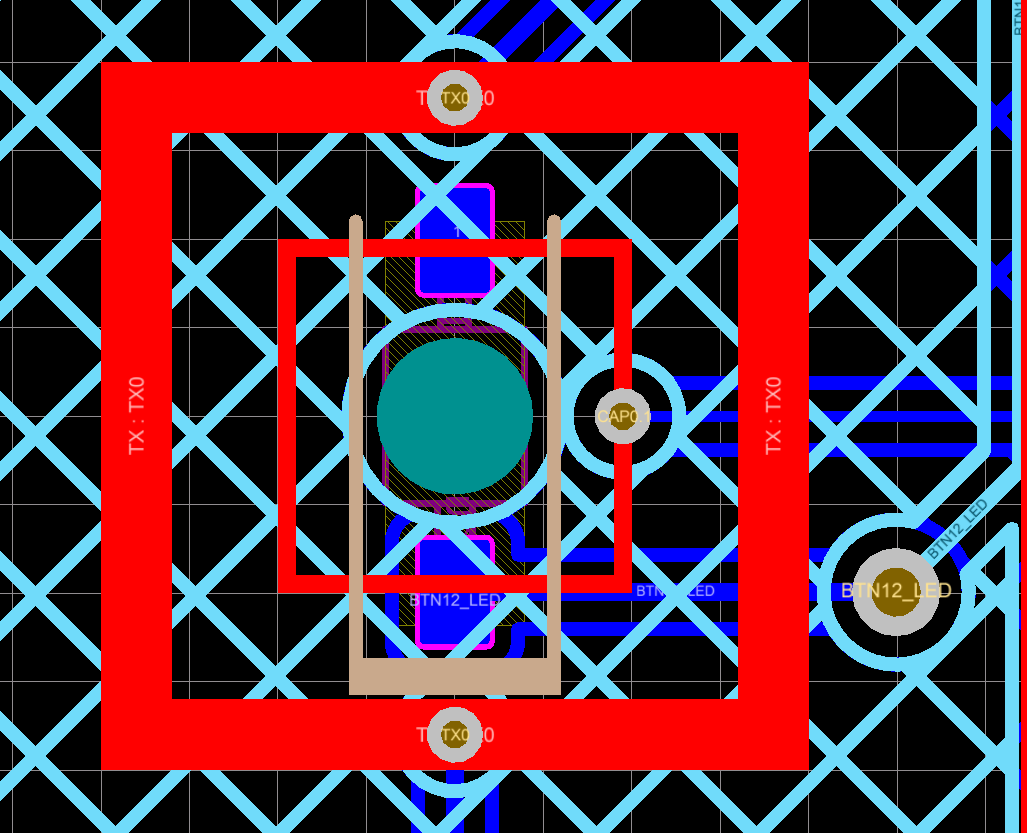

Currently my design is what is in the image it is 2 layers right now (red and green are the tracks). I am thinking of just putting the LED on a separate 3rd layer. Would this be enough to to ensure it operating as it should. As can be seen the LED is currently going to be directly below the touch pad (green), however this is needed due to size constraints. Also even with the 3rd layer I will have tracks running to the capacitor but they will likely go within a millimetre of the capacitive touch traces but on a separate layer, will this cause any problems?

Thanks for your advice!