Hello,

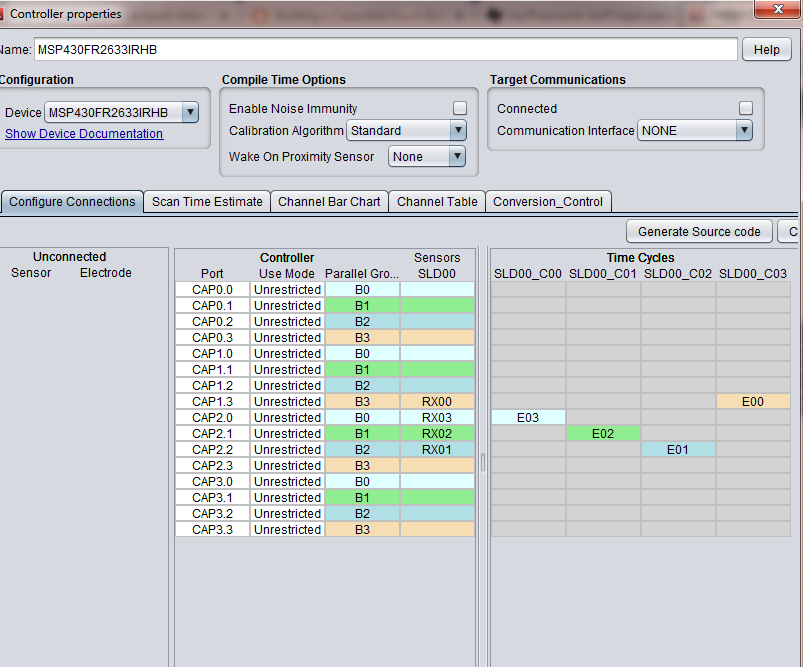

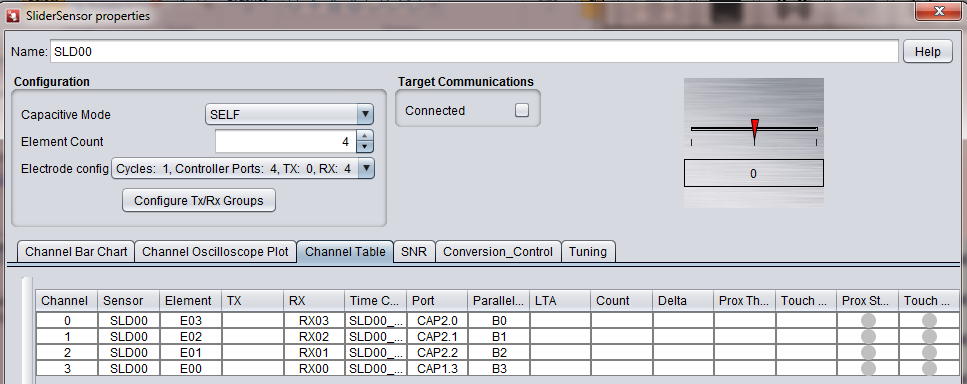

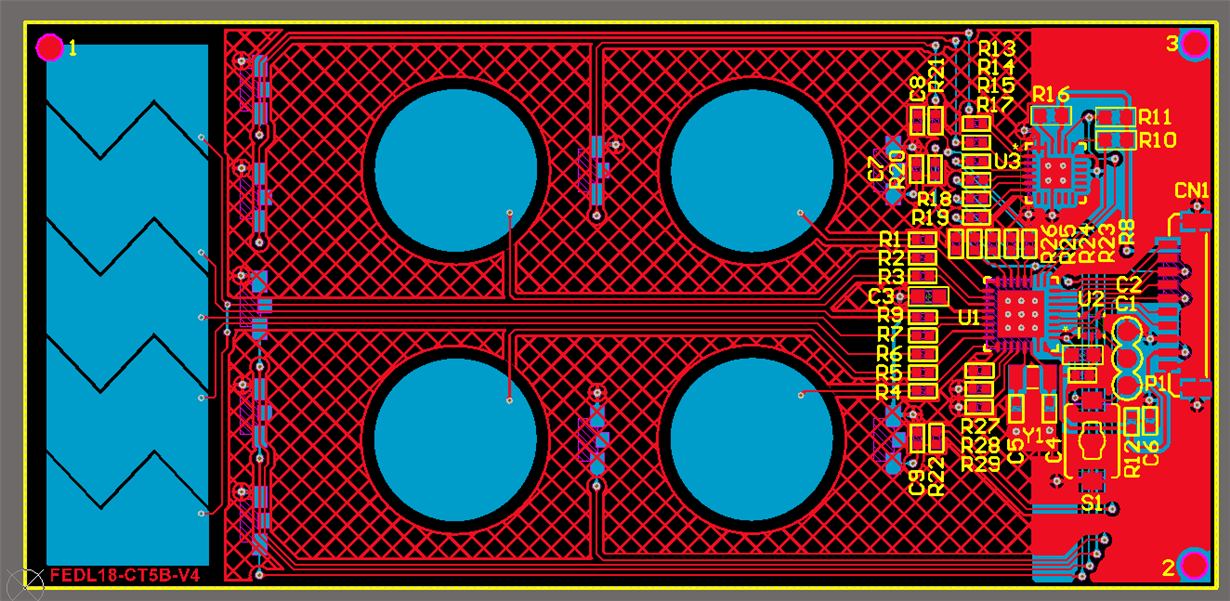

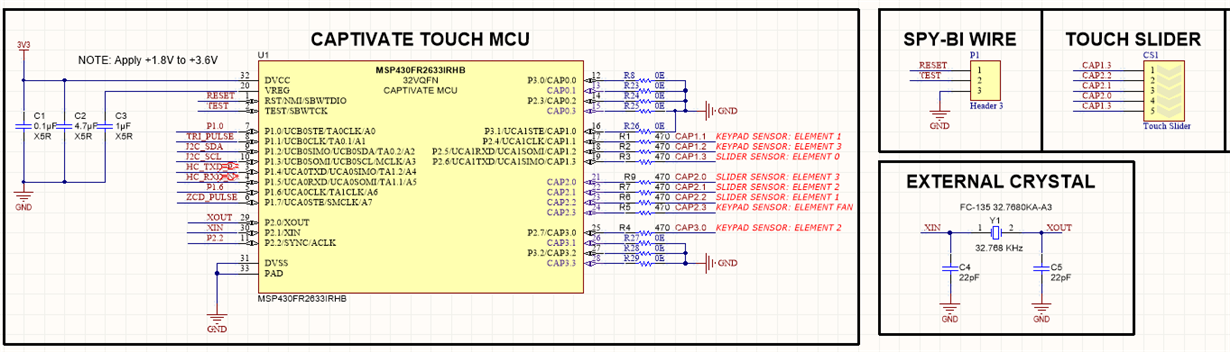

I have a designed a pcb which consist of 1 slider with CAP I/O as defined below. In capativate design center I have assigned the CAP I/O's as shown below in the picture. The problem here is unable to get proper values at the start and end points. ie the slider shows approximate 700 to 800 value at both the ends and at one end (ie start of slno 5 (Element 0)) the slider shows approximate 25 to 30 value. Resolution is 1000. and rest parameters are default values.

Tool versions

CCS v8.2.0.00007

captivate design center v1.6

| Slno. | Elements | CAP I/O |

| 1 | 0 | CAP 1.3 |

| 2 | 1 | CAP 2.2 |

| 3 | 2 | CAP 2.1 |

| 4 | 3 | CAP 2.0 |

| 5 | 0 |

CAP 1.3 |

In Design center

B.R

Gourav