Hi,

Background

An existing design had the XT2 crystal changed to adjust the clock frequency and units began no longer being able to start the crystal. Upon review, the load caps were adjusted slightly to account for trace capacitance which alleviated some of the boards with startup issues, but not all are functioning properly.

Steps Taken

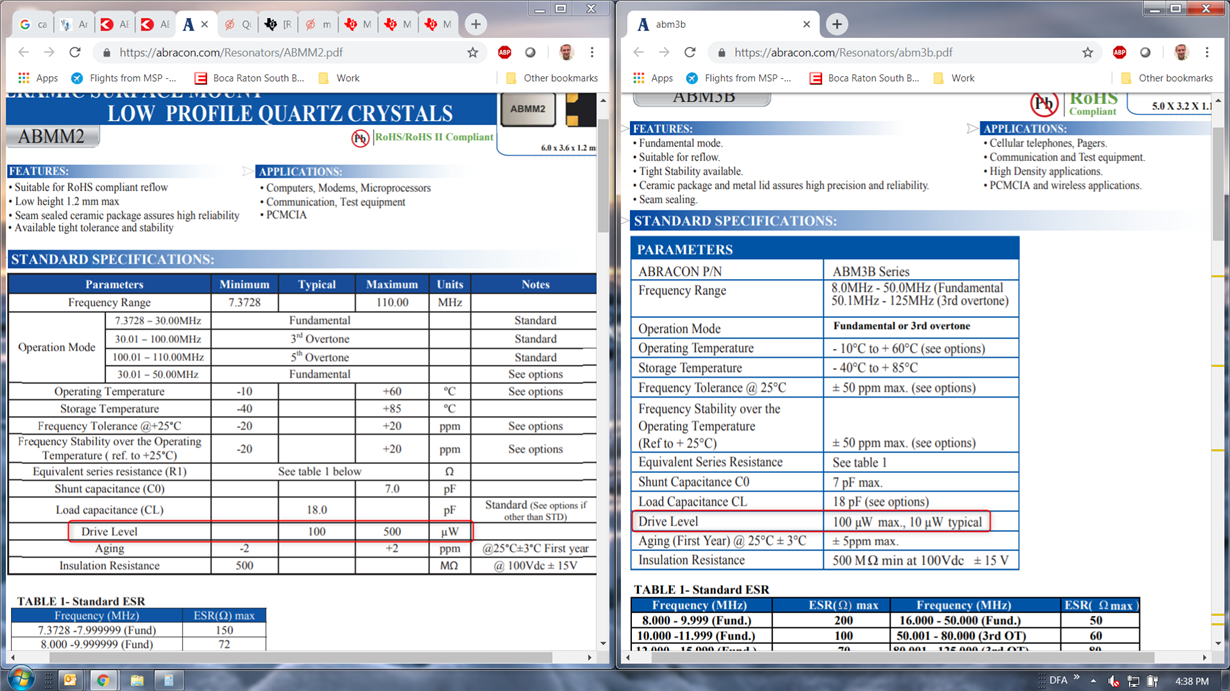

- Existing crystal ABM3B-8.000MHZ-B2-T was changed to ABMM2-7.3728MHz-E2-T

- An adjustment of the existing 33pF load capacitors to 27pF capacitors to account for trace capacitance

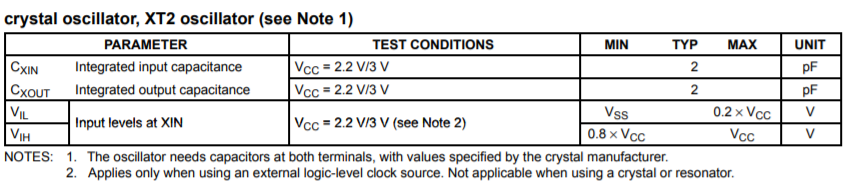

- Review of the 'F1611 datasheet, XT2 section for drive strength details:

- Review of the ABM3B and ABMM2 datasheets for crystal differences:

Questions

- Is drive strength data of the XT2 peripheral available for the 'F1611 device, or some indication of the maximum supported drive level of a crystal on XT2?

- Are any other parameters of the crystal critical to being supported by the 'F1611 device?

Best Regards,

Mark-