Other Parts Discussed in Thread: FLOWESI-GUI, MSPWARE, MSP430FR6989, EVM430-FR6989

Hi all!

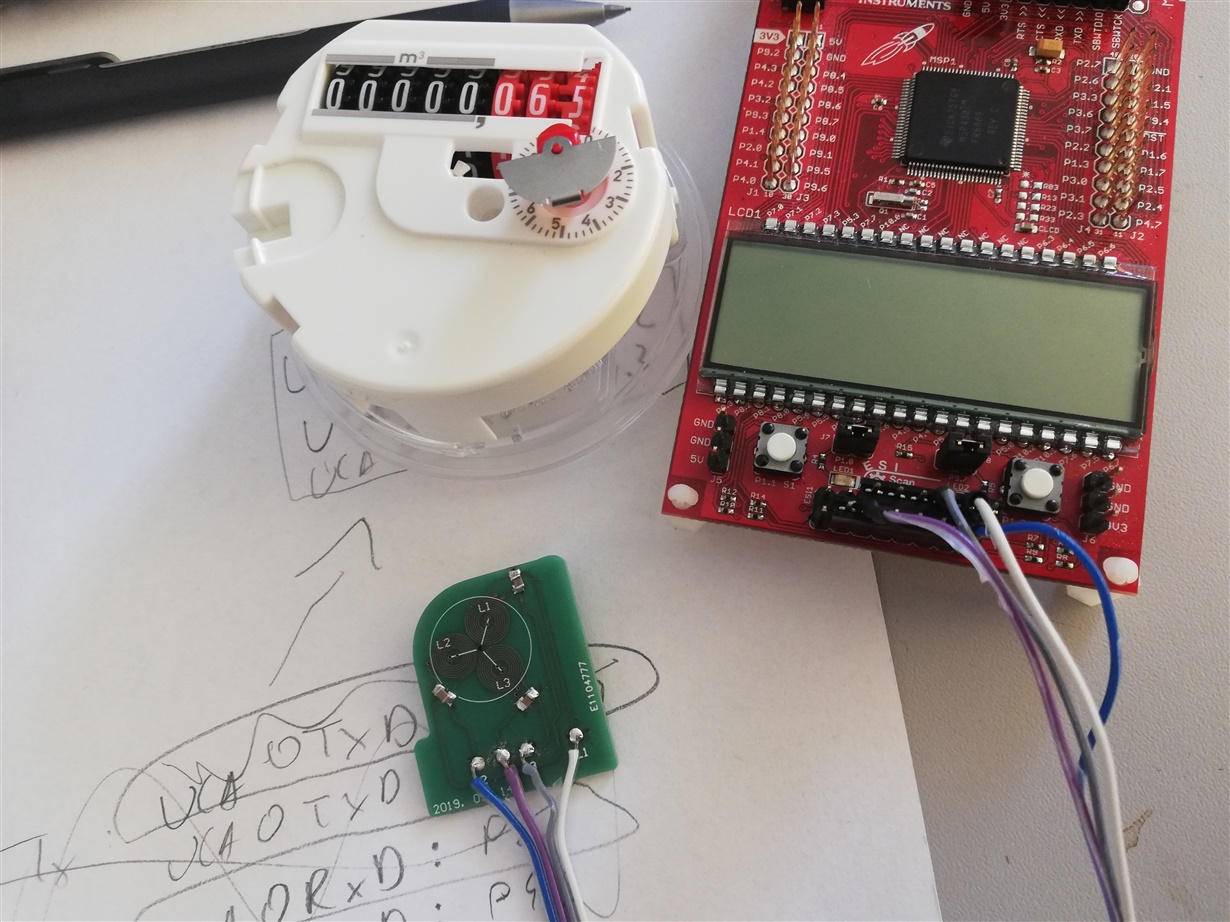

I am working on a water meter and I would like to achive rotation detection / read rotation disk. I would like to count the amount of rotationd it did, and the current position of the disk.

I tried to use the ESI modul of the 6989 launchpad, with the FLOWESI-GUI generated code. I have a hard time getting started.

Is there any example code, that helps getting started/ any turorial video?

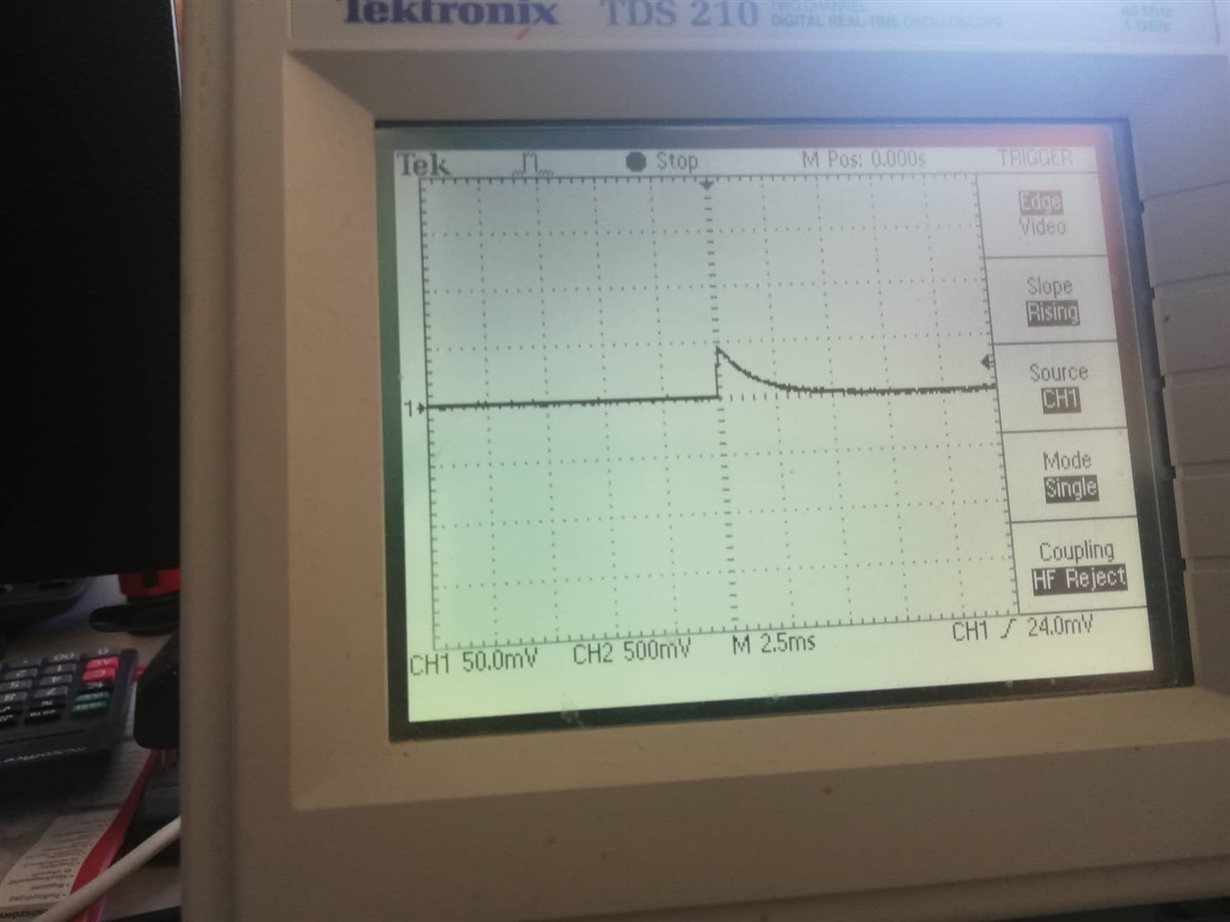

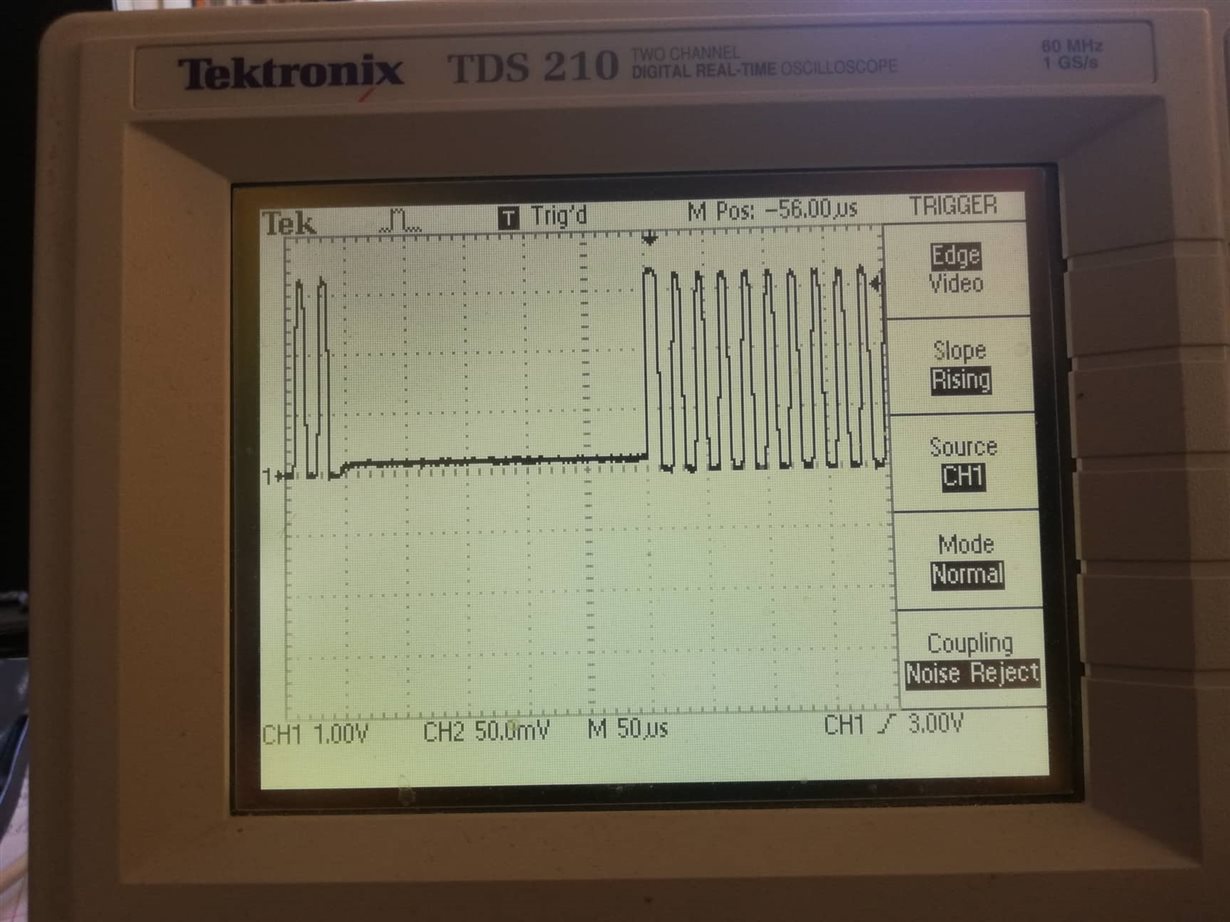

I am using 6989 launchpad with a 3 LC sensor, the sensors are 120 degrees apart. I am attaching a picture of my hardware setup.