Hello,

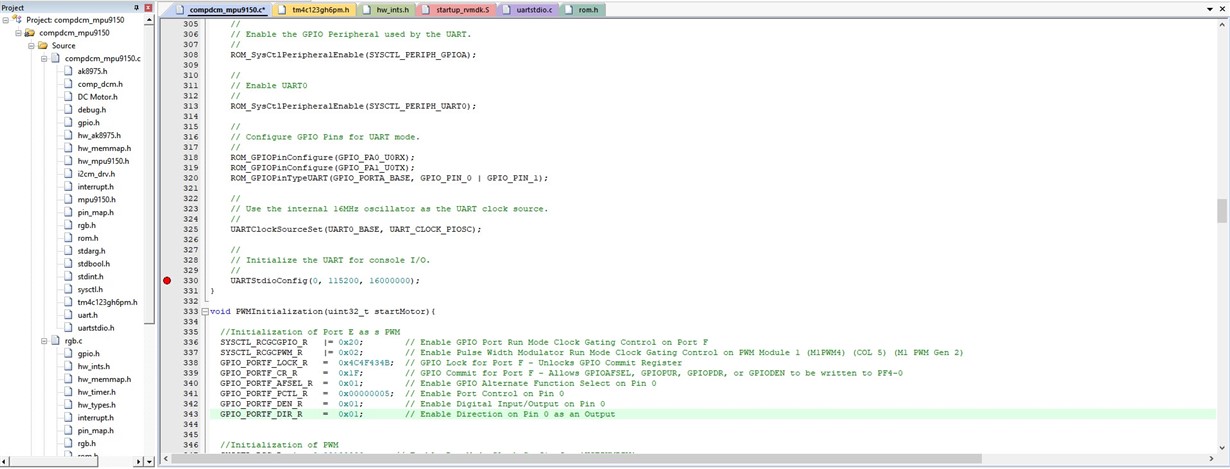

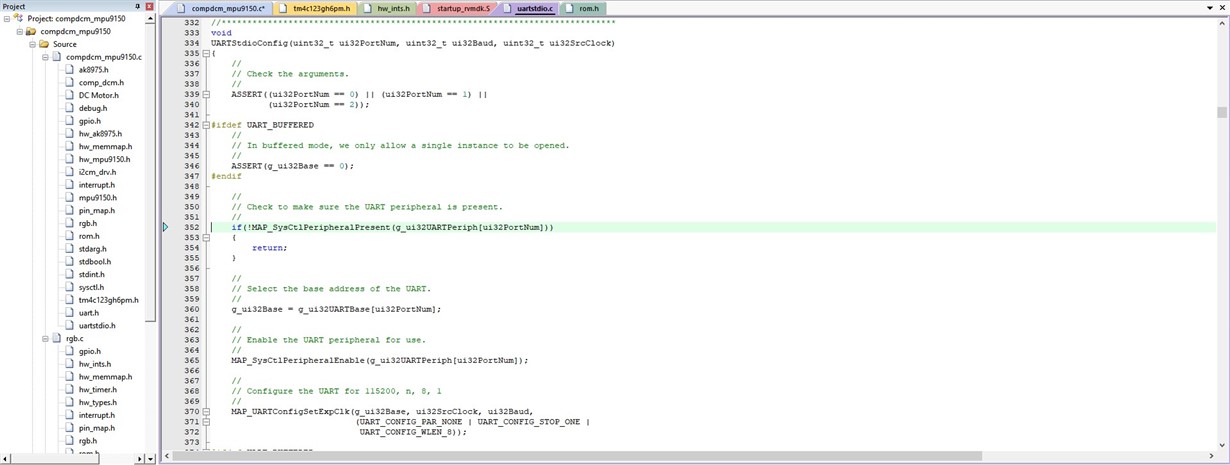

I'm currently using the TM4C123GXL with the Sensor Hub's gyroscope. However, I want to be able to use the gyroscope along with a PWM and at certain angles, produce a specific PWM output. Coding is not my issue, it's the fact that when I debug, there are no PWM registers to be evaluated. I'm using the compdcm_mpu9150 file that is included in the TI folder.

I simply want to be able to use the gyroscope as well as the PWM.

Has anyone else had this issue? If so, how would I enable my PWM registers so I can utilize them?

Thank you in advance.

Mitchell