Other Parts Discussed in Thread: STRIKE, UNIFLASH

Hi team,

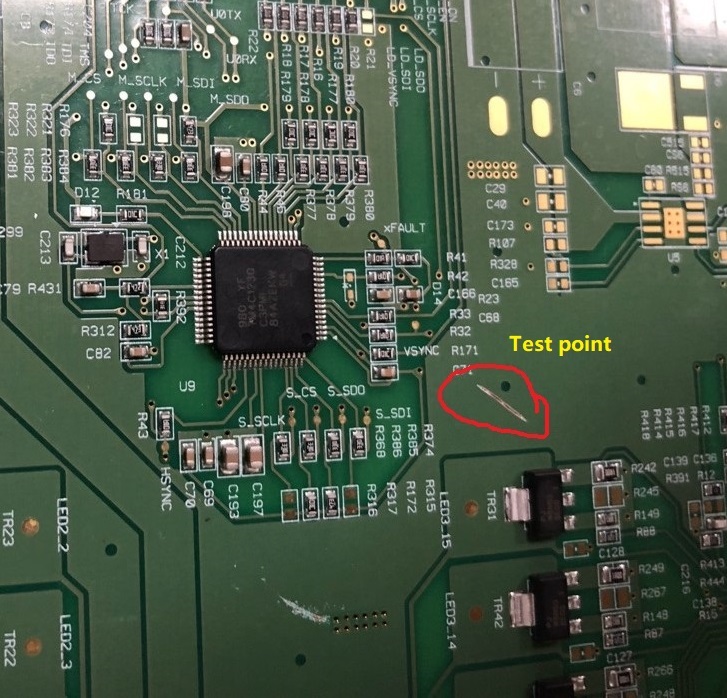

Our customer find TM4C1230C3PM ESD failure, failure rate 2/3. When the board under 6kV, TM4C1230C3PM cannot work. If customer download code again, the bad IC will work normally. Customer test many times, confirm the failure is recoverable.

I assumed it is caused by memory issue. Could you give some comments?

Thanks,

Miranda