Other Parts Discussed in Thread: DRV8353

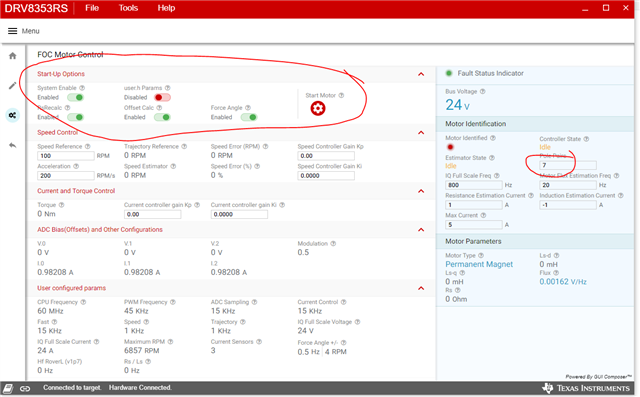

- It seems the PC tool DRV8353Rx has some auto motor characterize feature, but it is not clear how to use it, do you know where I can find instructions on that so the motor characteristics are measured? And I see no option to use hall sensors, do you know how I should select that.

- It also seems the user.h file is very important, but I don’t really understand it’s role, or how it is set up, I can’t find instructions for that.

- Do you know if this eval board is prone to failure, sounds like the gate driver in particular may fail easily?

- I have 48V 2A supply connected to it and a pretty beefy BLDC motor that I had lying around until our actual motors arrive, and I was clicking around the PC tool and it seemed to start some auto motor characterization routine. The motor never spun really, just shook around a little, I don’t believe it was trying to use the hall sensors, and I haven’t shorted R48, R50, and R52 yet, so the hall sensors were not available. After that routine stopped I tried to command the motor to spin and it just jumped a little and now the fault LED turns on (PC Tool indicates GDF, gate drive fault) and the motor does not move at all. I believe something on the board burned out.

I have a second board, but doing some research on the forums it seems like this board might fry easily? A lot of threads mentioned the current limit defaults to the maximum and the board can burn itself out? But I see there is a fuse on the board, so I wouldn’t think it should be able to do that, but it seems a lot of people are having this problem anyway. So I want to make sure I am doing the right sequence. It seems for the motor profiler I need to configure multiple things and I am not sure what to do with the information after it is done, does it get saved to user.h automatically when it is done?