Hello,

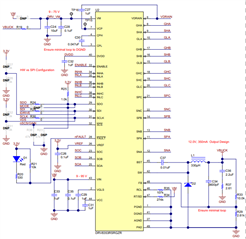

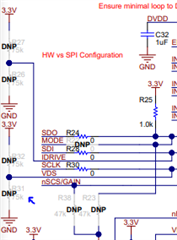

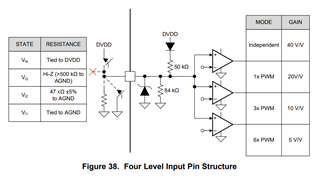

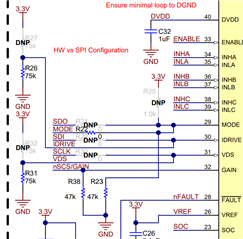

I have two DRV8353RH-EVM boards and am encountering same problem in both. I am using the default settings, I have not touched anything in the board.

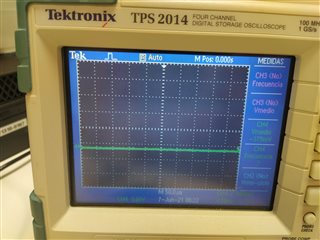

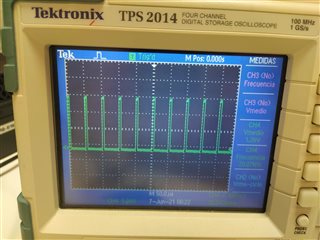

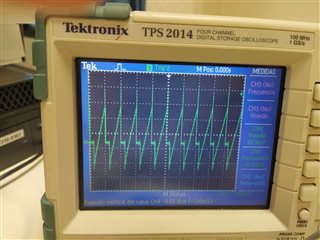

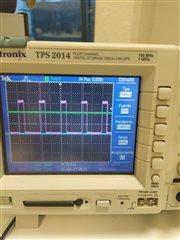

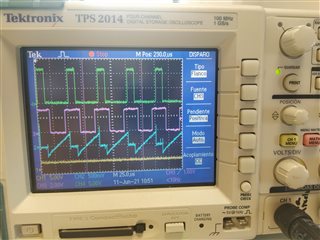

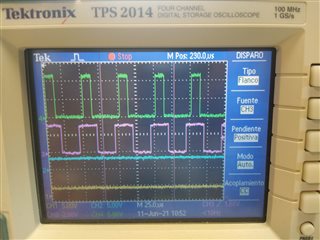

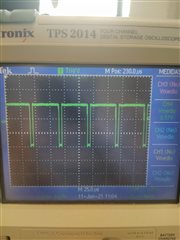

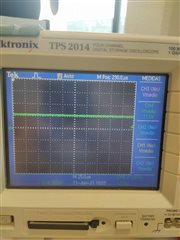

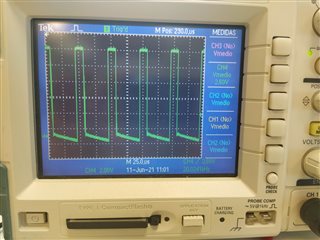

I am generating good INHX and INLX with Simulink for the 3x PWM mode (Default mode). I have measured values in oscilloscope and everything is fine in the ISOF28027 part. However, I am not getting GHX and GLX proper values. Many things are happening.

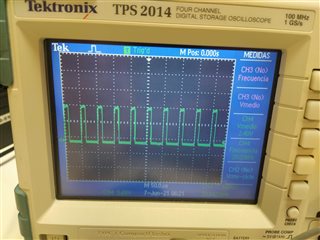

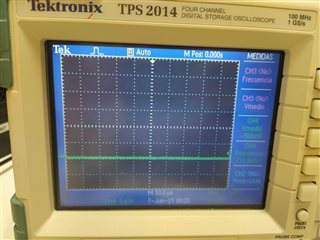

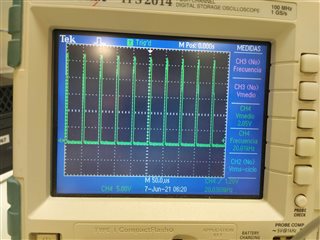

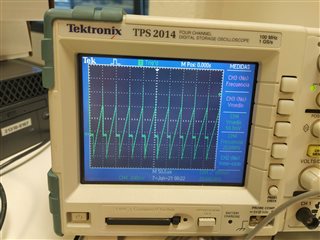

When i generate an ePWM of %50 duty cycle, for the three phases, I am getting a good result in GHA and GLA. B has no response at all and GLC is oscillating as it is supposed to be. GHC is getting some kind of triangular signal.

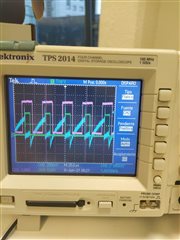

When different duty cycles are generated for each phase, we measure in GLC what it was supposed to be measured in GLB. GHC stays the same as before and GLB and GHC have no response. Once again, GHA and GLA work well.

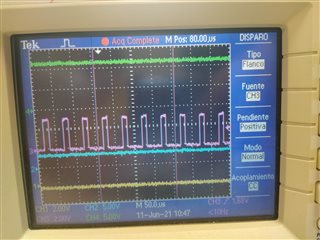

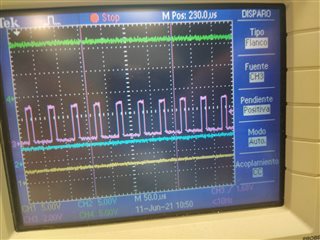

When sinusoidal reference is used, Phases A and B do have some kind of pattern, but it is not exactly the SPWM that it was supposed to be. Phase C stays the same, semi triangular GHC and GLC is constant at about 11 V.

I have been trying to solve the issue the past weeks but find no answer, it's been quite frustrating. I have found nothing in the forums.

I really hope you can help me.

Jon